*waves*

I ran my MR2 on an ST205 ECU for ages.

If you've seen the side-by-side comparison rolling road print outs between the two ECUs, they were probably mine.

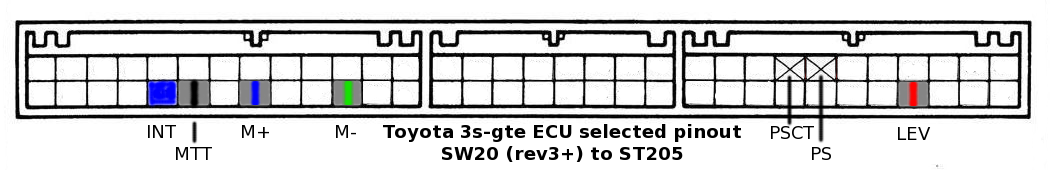

You only need to disconnect one of the two PS pins but I can never remember which one

- but you've already worked that out!

The INT pin replaces the FAN pin, so you lose your connection from the ECU to the engine bay fan controller.

This is no big deal

- the fan controller runs autonomously.

Some of the pins used for pump monitoring

(M+, M- and MTT) I think overlap with pins that are identified as part of the interface between the MR2 ECU and the

(optional) traction control ECU.

As I've never played with an MR2 with TRC and only actually know of one person with rev3+ TRC, this never bothered me.

You can't use the chargecooler and the Toyota TRC together for another reason anyway

- the TRC incorporates a 2nd throttlebody with its own throttle position sensor which would encroach into the space the core fits in.

I rebuilt my pump loom using resistive wire rather than inline resistors as it is from the factory

- the ancient resistors had crumbled to pieces and I thought resistive wire coated in heatshrink would be a bit more weatherproof.

The ST205 aircon setup is identical, but the power steering pump has an additional idle up valve on it which is another difference between the two ECUs.

Oh and just to check, you are using a JDM ST205 ECU, right? Otherwise you'll lose power!

I know of someone else who's since done this ECU conversion

(also on a cari blue rev3!) who didn't have the idle speed problems I encountered.

I'm interested to hear how your car idles once the weather has improved a bit.

RST wrote:There must be an easier way, the CC pump in my ST205 WRC I just bought comes in at about 1,000rpm then waits about 30s then stops.

If I recall the a'PEXI RSM I had years ago and simlar devices have PnP's

(or NpN's) which can be set to various trigger limits, if you use something like that via a relay then you will have something very similar and simple wiring?

Then there'd be no mucking about with the car's wiring with similar end effect?

Changing the ECU is the right way to do it IMO, if your intention is to run the chargecooler and retain stock Toyota management.

The pump doesn't kick in at 1000rpm, otherwise it would be on constantly at cold idle.

There's more logic behind it than that

(it's throttle driven not rpm driven for starters).

Combine that with warning lights for low coolant level and pump failure, a measurable power increase and a tangible effect in engine smoothness, it's pretty good for

£50.