V8 Mk1 6 speed with power steering

Moderators: IMOC Moderators, IMOC Committee Members

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

The original Mk1b unit Mart, i could fit a Mk2 servo or even a Camry one but i feel the Mk1b unit is well suited to the job.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

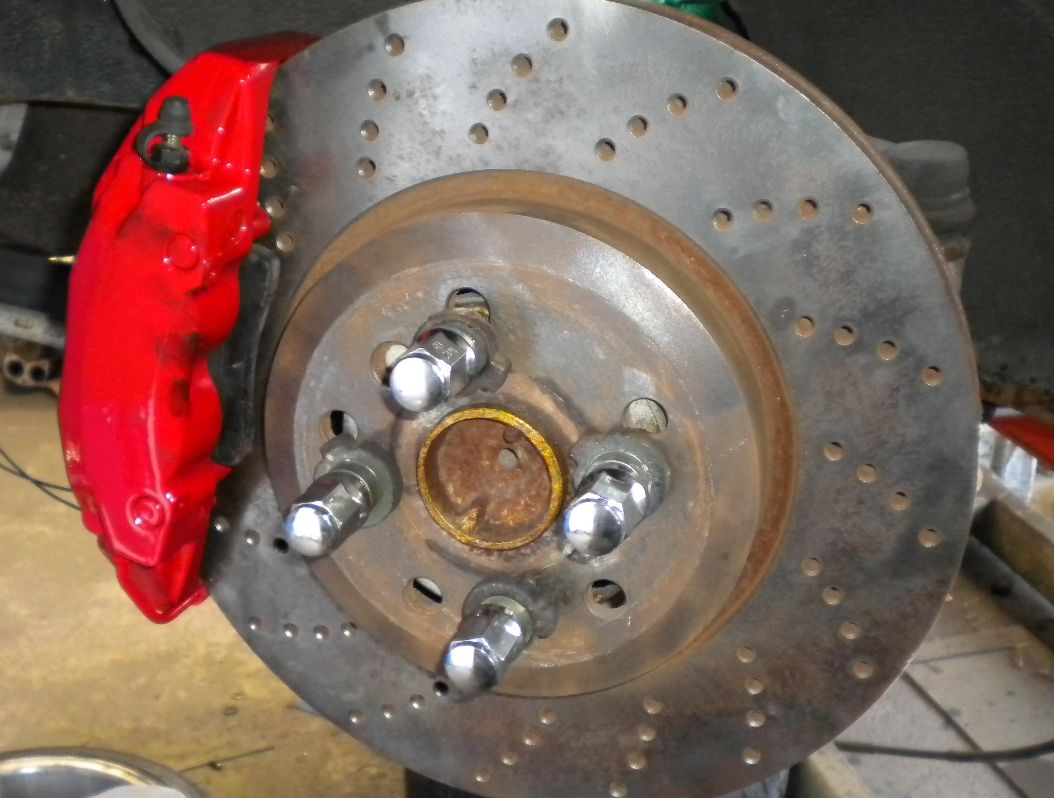

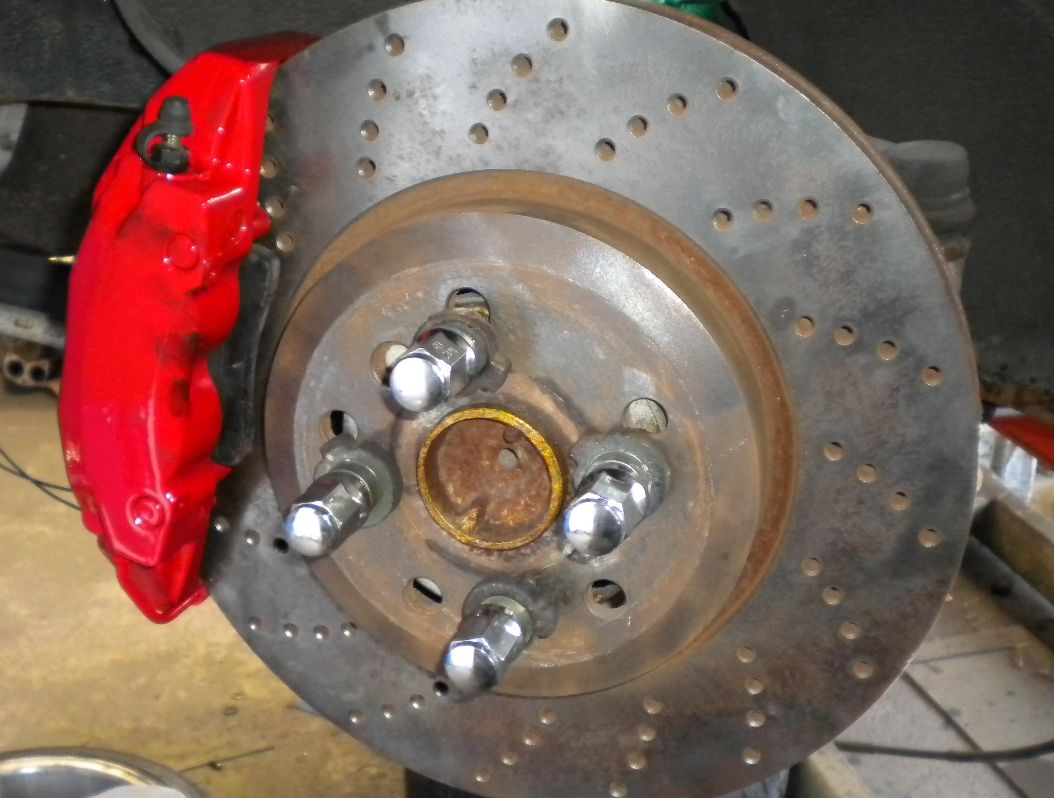

A couple of pics of my caliper adaptor brackets, i made these by bolting a plate to the hub, and a plate to the caliper which was aligned perfectly onto the disc, then the two plates were welded together. I V'd the plates both sides for maximum penetration and then added the end gussets for support afterwards.

I V'd the plates both sides for maximum penetration and then added the end gussets for support afterwards. The hub mounting has the stock bolt thread tapped into it and the caliper mounting has a 1.5x12 thread on its high tensile bolt which has a close fitting shoulder inside the caliper.

The hub mounting has the stock bolt thread tapped into it and the caliper mounting has a 1.5x12 thread on its high tensile bolt which has a close fitting shoulder inside the caliper.

Re: V8 Mk1 6 speed with power steering

Hey Paul is there a 5 stud conversion that will fit the mk1 hubs? I know you've done lots of these big brake conversions but it just seems wrong to me redrilling the discs. There are huge forces going through the discs when braking and in some locations there can't be a lot of material left between the drilled hole and the original hole.

There are huge forces going through the discs when braking and in some locations there can't be a lot of material left between the drilled hole and the original hole. I'd be worried if there are any insurance issues for this sort of mod.

I'd be worried if there are any insurance issues for this sort of mod. Or as an alternative can you plug weld the redundant holes without distorting the discs.

Or as an alternative can you plug weld the redundant holes without distorting the discs.

Edit: Just had another look at the drilling and I'm more concerned than ever. There are a couple of basic rules used in structural engineering concerning spacing of holes and distances to the edges of material and I think you would be struggling to comply with them.

There are a couple of basic rules used in structural engineering concerning spacing of holes and distances to the edges of material and I think you would be struggling to comply with them.

Not that I'm saying you need to but viewing it from an engineering perspective then I think you should at least consider it.

I am ignoring the clamping effect that the rim and wheel nuts have when properly torqued up and assuming worst case situation where all of the braking force is transmitted to the hub as a shear force through the studs.

Roughly speaking the space between the centres of holes should not be less than 2.5 times the diameter of the stud. So for example if your studs are 10mm diameter then you should have 25mm centre to centre as a minimum.

So for example if your studs are 10mm diameter then you should have 25mm centre to centre as a minimum. You definately have one hole that wouldn't satisfy that and another that is slotted so can't really be considered as a standard clearance hole.

You definately have one hole that wouldn't satisfy that and another that is slotted so can't really be considered as a standard clearance hole. Factor in that the discs were designed for 5 studs and you are using 4 then you are 20% down on the design capacity straight off.

Factor in that the discs were designed for 5 studs and you are using 4 then you are 20% down on the design capacity straight off.

I'd say 2 of your 4 holes can't be considered as giving you a good bearing contact under braking. So I think the majority of the effort required to resist shear under braking is being transmitted through 2 studs.

So I think the majority of the effort required to resist shear under braking is being transmitted through 2 studs.

All a bit theoretical and geeky I know but worst case scenario you have only got about 40% capacity and a very uneven load distribution through the discs.

Please give it some consideration, this is a monster you've created and needs all these safety issues addressed.

Alan

Edit: Just had another look at the drilling and I'm more concerned than ever.

Not that I'm saying you need to but viewing it from an engineering perspective then I think you should at least consider it.

I am ignoring the clamping effect that the rim and wheel nuts have when properly torqued up and assuming worst case situation where all of the braking force is transmitted to the hub as a shear force through the studs.

Roughly speaking the space between the centres of holes should not be less than 2.5 times the diameter of the stud.

I'd say 2 of your 4 holes can't be considered as giving you a good bearing contact under braking.

All a bit theoretical and geeky I know but worst case scenario you have only got about 40% capacity and a very uneven load distribution through the discs.

Please give it some consideration, this is a monster you've created and needs all these safety issues addressed.

Alan

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Thanks for your observations alan, always greatly appreciated.

On Twobrutal members have been modifying brakes this way for years, my very first 1.5 had drilled discs and although from an engineers point of view it isn't strictly correct we have tried to break things to destruction and it just doesn't happen.

There is a well known brake upgrade supplier for the Mk1 that actually supplies drilled discs (PCD face that is) but i'm not naming as it's not relevant so in my mind i'm confident that everything is safe.

(PCD face that is) but i'm not naming as it's not relevant so in my mind i'm confident that everything is safe. I don't like to chance anything though so we go through years of doing these things and testing them out.

I don't like to chance anything though so we go through years of doing these things and testing them out. There are about 50-60

There are about 50-60  (rough guess) Mk1 big brake conversions out there running drilled discs etc without a single issue.

(rough guess) Mk1 big brake conversions out there running drilled discs etc without a single issue.

Now please don't get me wrong alan, i am not trying to defend what we do, and your opinion is very important to me (i remade an entire engine cradle and my alternator bracketry because of it!)

(i remade an entire engine cradle and my alternator bracketry because of it!)  , but we have huge confidence in this sort of setup as do other owners who have put tens of thousands of miles on their upgrades.

, but we have huge confidence in this sort of setup as do other owners who have put tens of thousands of miles on their upgrades.

In short i don't think this needs addressing, but please, i hugely respect your input

On Twobrutal members have been modifying brakes this way for years, my very first 1.5 had drilled discs and although from an engineers point of view it isn't strictly correct we have tried to break things to destruction and it just doesn't happen.

There is a well known brake upgrade supplier for the Mk1 that actually supplies drilled discs

Now please don't get me wrong alan, i am not trying to defend what we do, and your opinion is very important to me

In short i don't think this needs addressing, but please, i hugely respect your input

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Alan, how would you feel about me welding all of the spare holes up and having the faces machined?

Re: V8 Mk1 6 speed with power steering

I'd say 2 of your 4 holes can't be considered as giving you a good bearing contact under braking.

I am ignoring the clamping effect that the rim and wheel nuts have when properly torqued up and assuming worst case situation where all of the braking force is transmitted to the hub as a shear force through the studs.

Agreed that the disc conversion 5 stud to 4 stud doesn't look very pretty but it's pessimistic to consider the braking load is carried in shear by the studs as the load is actually carried by friction between the wheel, the disc and the hub flange.

Re: V8 Mk1 6 speed with power steering

PW@Woodsport wrote:Alan, how would you feel about me welding all of the spare holes up and having the faces machined?

Yep that would be good that's what I was referring to by plug welding the spare holes, only worry was with distortion would be a slow process.

scomr2 wrote:Agreed that the disc conversion 5 stud to 4 stud doesn't look very pretty but it's pessimistic to consider the braking load is carried in shear by the studs as the load is actually carried by friction between the wheel, the disc and the hub flange

Yes also agree but my thinking was that Paul, if he's anything like me, would grease up the mating faces between the hub and the disc so that they don't rust together therefore you could argue that under the worst of conditions you might create a slip plane and the discs could bear directly on the studs

The brackets Paul has fabricated I think are ok, I would probably have gone for a slightly different design and arrangement of the stiffeners but not having seen how the calipers connect to the bracket I'm confident Paul has it covered.

Alan

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Cheers chaps, i really don't mind people picking up on possible flaws on this build, it's all very constructive.

I agree the 5 to 4 stud looks unsightly but my fear in welding the mating surface is causing distortion, so if i can get away without doing that i'd prefer to.

I have total faith in my caliper brackets, i've made these many times for radial mount conversions and i have been welding for over 20 years so all joins have been V'd and maximum penetration. The main weld between hub and caliper plates is a double run of weld, one right in the V groove and the second built up over that.

The main weld between hub and caliper plates is a double run of weld, one right in the V groove and the second built up over that.

I also put one of my previous brackets into a 50 ton press last year ( i drilled a hole slightly off so it was scrap, only fit for testing) and it took the full 50 tons without braking welds or even bending

( i drilled a hole slightly off so it was scrap, only fit for testing) and it took the full 50 tons without braking welds or even bending  (press was applied over the whole bracket, not just one point on it).

(press was applied over the whole bracket, not just one point on it).

So i have no issue at all with the brackets, they are bombproof. I could add a middle gusset if need be but i think it's overkill, are my front brakes ever likely to exceed 50 tons of force on the bracket?

I could add a middle gusset if need be but i think it's overkill, are my front brakes ever likely to exceed 50 tons of force on the bracket?

I'll consider welding the spare holes up alan

I agree the 5 to 4 stud looks unsightly but my fear in welding the mating surface is causing distortion, so if i can get away without doing that i'd prefer to.

I have total faith in my caliper brackets, i've made these many times for radial mount conversions and i have been welding for over 20 years so all joins have been V'd and maximum penetration.

I also put one of my previous brackets into a 50 ton press last year

So i have no issue at all with the brackets, they are bombproof.

I'll consider welding the spare holes up alan

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Calipers now painted with VHT caliper paint, pads fitted too. .

. .

.

A quick pic of my Azevs over the top of the brakes, these are 17" rims to give an idea of the size, i think they fill the rims quite well.

A quick pic of my Azevs over the top of the brakes, these are 17" rims to give an idea of the size, i think they fill the rims quite well.

Re: V8 Mk1 6 speed with power steering

with regards drilled brake discs. .

. .

.

at the very worse, there are generally only 2 holes at maximum that are drilled very close to other holes. one invariably is drilled into another, making it one large ugly hole.

one invariably is drilled into another, making it one large ugly hole. but there are always still 2 holes that are cleanly drilled.

but there are always still 2 holes that are cleanly drilled.

brake disc holes are never toleranced in the first place, manufacturer spec discs often have upto 2mm of clearance. because the disc has a hubcentric mounting to locate it, the bolt holes are essentially only there to allow the wheel studs to protrude for the wheels themselves.

because the disc has a hubcentric mounting to locate it, the bolt holes are essentially only there to allow the wheel studs to protrude for the wheels themselves. they double up in shear to stop the disc from rotating, but there is no chance the disc will ever move if the wheel is correctly torqued.

they double up in shear to stop the disc from rotating, but there is no chance the disc will ever move if the wheel is correctly torqued.

in order for the disc to move more than a few millimetres (which it is free to do even with stock discs due to oversized holes) it would have to overcome the following:

(which it is free to do even with stock discs due to oversized holes) it would have to overcome the following:

there would have to be more grip in the tyre than there is in the brakes in order for it not to simply just lock up. this is unlikely.

this is unlikely.

assuming the tyre holds traction, there would have to be more braking friction than there is friction holding the tyre in place on the rim. tyres can rotate on the rim if there is enough grip involved.

tyres can rotate on the rim if there is enough grip involved. and with the forces we are talking about here for the brake disc to fail

and with the forces we are talking about here for the brake disc to fail  (e.g.

(e.g. impossible loads), the tyre would probably just spin on the rim.

impossible loads), the tyre would probably just spin on the rim.

the disc would either have to break into pieces, or shear all 4 bolts to spin freely. otherwise the worse case scenario is just the disc rotating slightly.

otherwise the worse case scenario is just the disc rotating slightly. which it would do once on the first brake application, and then once butted up against the studs could not happen again.

which it would do once on the first brake application, and then once butted up against the studs could not happen again.

if it were possible to shear all 4 bolts with a re-drilled disc, then it would be equally as possible with a standard disc. and theres no way the brakes would be able to generate enough force to achieve this unless you were running carbon/carbon brakes, in which case youd have correctly made bells anyway.

and theres no way the brakes would be able to generate enough force to achieve this unless you were running carbon/carbon brakes, in which case youd have correctly made bells anyway.

finally, drive forces from a V8 most probably exert more stress on the studs than a brake disc could. hence why higher powered cars tend to have 5 stud wheels, and why high powered race cars using drive pegs and centrelock nuts.

hence why higher powered cars tend to have 5 stud wheels, and why high powered race cars using drive pegs and centrelock nuts. ultimately though you cant transmit those forces unless the tyres maintain traction with the road surface.

ultimately though you cant transmit those forces unless the tyres maintain traction with the road surface. as soon as the wheel spins the force reduces significantly.

as soon as the wheel spins the force reduces significantly. so unless Paul plans to run 8" slicks i dont see any possible problems.

so unless Paul plans to run 8" slicks i dont see any possible problems.

so basically its a complete non-issue. its unsightly

its unsightly  (although cant be seen once the wheel is on anyway), and from an engineering perspective is definitely not ideal.

(although cant be seen once the wheel is on anyway), and from an engineering perspective is definitely not ideal. you wouldnt see a manufacturer using such practices from the factory, thats for sure.

you wouldnt see a manufacturer using such practices from the factory, thats for sure. but from a modification standpoint it is of no consequence.

but from a modification standpoint it is of no consequence. it is no less safe than the stock setup.

it is no less safe than the stock setup. considerably more dangerous than drilled out discs are people that run stock brakes and suspension on cars with substantial power upgrades

considerably more dangerous than drilled out discs are people that run stock brakes and suspension on cars with substantial power upgrades  (which happens a lot more commonly!), and even more dangerous than that are usually drivers themselves lol.

(which happens a lot more commonly!), and even more dangerous than that are usually drivers themselves lol.

at the very worse, there are generally only 2 holes at maximum that are drilled very close to other holes.

brake disc holes are never toleranced in the first place, manufacturer spec discs often have upto 2mm of clearance.

in order for the disc to move more than a few millimetres

there would have to be more grip in the tyre than there is in the brakes in order for it not to simply just lock up.

assuming the tyre holds traction, there would have to be more braking friction than there is friction holding the tyre in place on the rim.

the disc would either have to break into pieces, or shear all 4 bolts to spin freely.

if it were possible to shear all 4 bolts with a re-drilled disc, then it would be equally as possible with a standard disc.

finally, drive forces from a V8 most probably exert more stress on the studs than a brake disc could.

so basically its a complete non-issue.

Re: V8 Mk1 6 speed with power steering

Jim-SR wrote:with regards drilled brake discs..

.

so basically its a complete non-issue.its unsightly

(although cant be seen once the wheel is on anyway), and from an engineering perspective is definitely not ideal.

you wouldnt see a manufacturer using such practices from the factory, thats for sure.

but from a modification standpoint it is of no consequence.

it is no less safe than the stock setup.

considerably more dangerous than drilled out discs are people that run stock brakes and suspension on cars with substantial power upgrades

(which happens a lot more commonly!), and even more dangerous than that are usually drivers themselves lol.

So we agree that the disc drilling is a non issue but what about the welded caliper bracket?

50 tons of force is meaningless without knowing how it was applied and fatigue is the more likely issue rather than ultimate strength anyway.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

I've made MANY caliper mounting brackets this way on cars that have done motorsport and covered tens of thousands of miles without issue. .

. .

. .

. i really don't see how they could be a problem? It's not like i've just snotted two pieces of thin steel together, and if a bearing press that exerts 50 tons of pressure onto it cannot even bend it at all i fail to see how it could fatigue over time?

i really don't see how they could be a problem? It's not like i've just snotted two pieces of thin steel together, and if a bearing press that exerts 50 tons of pressure onto it cannot even bend it at all i fail to see how it could fatigue over time?

I'm very happy with them.

Jim your post makes perfect sense, i agree drilling discs sounds bad and looks unsightly but the chance of failure is remote in the extreme, you would need to leave your wheel loose for a start, even then i can't see how it would fail if the disc was allowed to move, which it isn't.

I'm very happy with them.

Jim your post makes perfect sense, i agree drilling discs sounds bad and looks unsightly but the chance of failure is remote in the extreme, you would need to leave your wheel loose for a start, even then i can't see how it would fail if the disc was allowed to move, which it isn't.

Re: V8 Mk1 6 speed with power steering

If your 50 ton press test was done with the bracket bolted to the press bed and the load applied such as to open up the V then you have indeed tested the critical welds between the gussets and the two plates.

Just because one of your brackets passed the press test and MANY have not yet failed in fatigue does not mean that they never will.

What I was highlighting in my original post was risk level

What I was highlighting in my original post was risk level  - there is a low risk of failure of the studs in shear but a higher risk of failure of the bracket by fatigue.

- there is a low risk of failure of the studs in shear but a higher risk of failure of the bracket by fatigue.

Hopefully it will be fine!

Just because one of your brackets passed the press test and MANY have not yet failed in fatigue does not mean that they never will.

Hopefully it will be fine!

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Yep I put the full 50 tons right on the spine of the bracket and it laughed at it.

I have 100% faith in it, there is no record of any bracket like this suffering "fatigue"

"fatigue"  , I just can't see how it ever could, to be honest I'd say there's more chance of being killed by your trousers in terms of risk.

, I just can't see how it ever could, to be honest I'd say there's more chance of being killed by your trousers in terms of risk.

It's a non issue for me

I have 100% faith in it, there is no record of any bracket like this suffering

It's a non issue for me

Re: V8 Mk1 6 speed with power steering

Right so if it was loaded on the spine potentially the welds were not loaded at all  - you could take one gusset, stand it on end and apart from blunting the tip it should take the 50 ton load.

- you could take one gusset, stand it on end and apart from blunting the tip it should take the 50 ton load.

It's dangerous to underestimate fatigue failure - try reading this wiki page http://en.wikipedia.org/wiki/Fatigue_%28material%29

- try reading this wiki page http://en.wikipedia.org/wiki/Fatigue_%28material%29

Particularly read the paragraph on the collapse in 1980 of the oil

oil

platform

platform Alexander L.

Alexander L. Kielland where the failure was traced to a poorly made

Kielland where the failure was traced to a poorly made  6mm fillet weld

6mm fillet weld .

.

It's dangerous to underestimate fatigue failure

Particularly read the paragraph on the collapse in 1980 of the

Re: V8 Mk1 6 speed with power steering

Jim-SR wrote:

brake disc holes are never toleranced in the first place, manufacturer spec discs often have upto 2mm of clearance.because the disc has a hubcentric mounting to locate it, the bolt holes are essentially only there to allow the wheel studs to protrude for the wheels themselves.

they double up in shear to stop the disc from rotating, but there is no chance the disc will ever move if the wheel is correctly torqued.

discs just never move

at work we fit 800 bhp boat engines with 2500 ftlb of torque and the only thing holding gearbox flange to the prop shaft is 6 1/2inch diameter

Carry on Paul I want to see vids of this beast on a track

Re: V8 Mk1 6 speed with power steering

Wow I've really set the cat amongst the pigeons here, love an informed debate like this and hope it can stay on an even keel with not to many ego's being dented.

If I can attempt to summarise I think everyone is in agreement that my initial concern of the redrilling of the discs is not an issue in terms of the disc failing in any way due to shear at the studs.

I absolutely accept all the comments concerning that, but can I throw a couple of other thoughts into the mix.

I do feel that there is an increased risk, due to the redrilling, of the discs distorting prematurely.

1. Heat build up near the holes that are very close together.

Heat build up near the holes that are very close together. There is very little material there so under heavy braking instead of an even dissipation of the heat throughout the disc you will get localised hot spots and I think this is an area of weakness.

There is very little material there so under heavy braking instead of an even dissipation of the heat throughout the disc you will get localised hot spots and I think this is an area of weakness. Hence my suggestion to plug weld the redundant holes.

Hence my suggestion to plug weld the redundant holes.

2. The hub flanges are smaller than the mating face of the disc.

The hub flanges are smaller than the mating face of the disc. Therefore this face is not supported as fully as it was originally intended, which to me says a smaller area of contact

Therefore this face is not supported as fully as it was originally intended, which to me says a smaller area of contact  = reduced frictional resistance and increased overhang of the disc flange increasing the stresses in the disc.

= reduced frictional resistance and increased overhang of the disc flange increasing the stresses in the disc.

Everyday's a school day for me I'd gladly welcome any alternative thoughts even if it proves that I'm being way over cautious.

Alan

If I can attempt to summarise I think everyone is in agreement that my initial concern of the redrilling of the discs is not an issue in terms of the disc failing in any way due to shear at the studs.

I absolutely accept all the comments concerning that, but can I throw a couple of other thoughts into the mix.

I do feel that there is an increased risk, due to the redrilling, of the discs distorting prematurely.

1.

2.

Everyday's a school day for me I'd gladly welcome any alternative thoughts even if it proves that I'm being way over cautious.

Alan

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Ok Scomr2, i didn't have to want to resort to showing you a weaker production bracket, because my build is all about constructive criticism, which at the end of the day helps me build this car, but i feel you are just being argumentative for the sake of it now with no real reason for criticizing the brackets.

Please read this.

http://forums.vwvortex.com/showthread.php?4559419

They are proper caliper adapters that are available made out of thinner steel than i have used for the exact same caliper that i am using, oh and look. .

. .

. .

. it doesn't even have end gussets! Put 50 tons on the spine of those and see what happens.

it doesn't even have end gussets! Put 50 tons on the spine of those and see what happens. .

. .

. .

.

I'd also like to draw your attention to the fact that this kit doesn't even have shouldered bolts for the caliper, mine does.

Now if you'd excuse me i have a V8 Mr2 to finish.

Please read this.

http://forums.vwvortex.com/showthread.php?4559419

They are proper caliper adapters that are available made out of thinner steel than i have used for the exact same caliper that i am using, oh and look.

I'd also like to draw your attention to the fact that this kit doesn't even have shouldered bolts for the caliper, mine does.

Now if you'd excuse me i have a V8 Mr2 to finish.

Re: V8 Mk1 6 speed with power steering

PW@Woodsport wrote:Ok Scomr2, i didn't have to want to resort to showing you a weaker production bracket, because my build is all about constructive criticism, which at the end of the day helps me build this car, but i feel you are just being argumentative for the sake of it now with no real reason for criticizing the brackets.

Please read this.

http://forums.vwvortex.com/showthread.php?4559419

They are proper caliper adapters that are available made out of thinner steel than i have used for the exact same caliper that i am using, oh and look..

.

.

it doesn't even have end gussets! Put 50 tons on the spine of those and see what happens.

.

.

.

I'd also like to draw your attention to the fact that this kit doesn't even have shouldered bolts for the caliper, mine does.

Now if you'd excuse me i have a V8 Mr2 to finish.

Paul,

I'm not trying to be augmentative just highlight risk.

Your bracket is stiffer than the production bracket because of the gussets but stiffness does not mean strength.

Please feel free to carry on with your MR2 without continuing the

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Why do i get the feeling if i had made them out of 8mm angle iron with no gussets that you'd still have an issue with them?

I'm 100% happy with the strength of my brackets, the 50 ton press couldn't do anything to them and i have added gussets whereas the pictured ones don't. The plates are 12mm thick with full penetration on Vee'd edges, i also don't know anyone else that tries to break the part with extreme testing before fitting it to the car apart from the manufacturer.

The plates are 12mm thick with full penetration on Vee'd edges, i also don't know anyone else that tries to break the part with extreme testing before fitting it to the car apart from the manufacturer. I am totally happy i have done my best with these.

I am totally happy i have done my best with these.

It will be fine, if it's not you can point and laugh.

I'm 100% happy with the strength of my brackets, the 50 ton press couldn't do anything to them and i have added gussets whereas the pictured ones don't.

It will be fine, if it's not you can point and laugh.