My question is, can I put the wg onto one of the branches of the manifold, where it's easy to fit, or do I need to put it where the 4 branches meet?

Would there be issues if I fitted it to a single branch?

Thanks dylan

Moderators: IMOC Moderators, IMOC Committee Members

dylan5084 wrote:I know I'll need to weld up the internal gate.

sheppy wrote:Is it a rev2 you have? I have a stainles 4 branch manifold with a wastegate port on it, brand new and unused

shinny wrote:dylan5084 wrote:I know I'll need to weld up the internal gate.

That seems to be the general wisdom.I'm not sure why, though.

.

.

it just removes any flexibility

/ resale value in your setup later.

The actuator will keep the wastegate shut well enough.

(As well as it ever did, and people don't tend to complains about internal gates creeping open before)

I've got a GT28 turbo kit with external wastegate and still had bad boost creep..

.

so I've just taken the unusual step of adding an internal wastegate and running both the internal and external gates at the same time.

With a well chosen actuator pressure, it's working a treat!

I did get a CT20b converted to external gate and had the wastegate welded up..

.

and I regret that now, because noone wants to buy a turbo with a welded up wastegate

Sheppy is right though, you want to dump from all four runners if possible..

.

three might suffice, but one won't be good enough.

dylan5084 wrote:sheppy wrote:Is it a rev2 you have? I have a stainles 4 branch manifold with a wastegate port on it, brand new and unused

It is a rev 2, how much you after for it? Save a bit of faffing about!

dylan5084 wrote:So, with the actuator without vac pressure should this generally keep the internal wastegate shut?

dylan5084 wrote:

So, with the actuator without vac pressure should this generally keep the internal wastegate shut?

2mad wrote:The actuator spring will hold tension(the gate shut) best it can

.

.

you could fit shims

(shimming the wastegate) to hold it closed with more force

.

.

welding it shut after testing it works ok is probably your best bet.

shinny wrote:2mad wrote:The actuator spring will hold tension(the gate shut) best it can

.

.

you could fit shims

(shimming the wastegate) to hold it closed with more force

.

.

welding it shut after testing it works ok is probably your best bet.

Exactly how easily will the wastegate be pushed open? It's not like it's going to start opening at 0.5bar! Let's not forget that many owners regularly run 1.2bar with the standard actuator and no-one seems to complain about the actuator being pushed open early by the exhaust gasses.Without a vac hose on the actuator, the wastegate will be held shut more firmly than running MBCs or EBCs without much gain configured.

Why does it suddenly become a problem when there's another wastegate actually doing the boost control instead?

The reason I'm advising against welding is because I'm speaking from experience of someone who did get a CT series wastegate welded up to go external gate and wishes he hadn't.

With that said, shimming the actuator is a great idea if you're really worried about the wastegate being pushed open

Finally, if your creep is so bad that the external wastegate doesn't do the trick by itself(as mine didn't on my CT28 kit) then you always have the option of running both internal and external gates.

.

.

unless you weld up the turbine housing!

dylan5084 wrote:Is it possible I could buy an adapter plate to sandwich in between the turbo and manifold, with an offtake for the external wastegate there? Where would I source one of those?

Rob - East Coast Imports wrote:wastegates DO have a"cracking" pressure.

.

where they'll start to open, so for someone running 1ish bar it probably

is

somewhere around half a bar, internal gates don't just snap open at the desired pressure.

Rob - East Coast Imports wrote:as for the wastegate, a 38mm wastegate should be adequate for 99% of MR2 set ups, bearing in mind it'll need to be in a place on the manifold thatfeeds from all four runners, so you will loose some of the twin scroll effect.

sheppy wrote:entirely possible but you;d struggle to find a ct26 to ct26 adapter, if you took that manifold off me you could easily get a T3 to CT26 adapter

Bear in mind your turbo will sit lower and in turn so will your decat which then won't line up with your exhaust.

http://www.ebay.co.uk/itm/CT-26-to-T3-C ... 1e89f44851

although..

.If you got one of these made up

(or bought this one) then I doubt you'd have to modify the downpipe at all.

dylan5084 wrote:sheppy wrote:entirely possible but you;d struggle to find a ct26 to ct26 adapter, if you took that manifold off me you could easily get a T3 to CT26 adapter

Bear in mind your turbo will sit lower and in turn so will your decat which then won't line up with your exhaust.

http://www.ebay.co.uk/itm/CT-26-to-T3-C ... 1e89f44851

although..

.If you got one of these made up

(or bought this one) then I doubt you'd have to modify the downpipe at all.

Looks a not bad option that countersunk plate, you make a not bad salesman

shinny wrote:

Cracking pressure, AFAIU, is all about when the wastegate starts to move when applying boost pressure to it.So yes, a 1bar actuator will start moving at around 0.5bar boost.

This is why EBCs have the concept of gain.

However, that's not what we're talking about here

- I'm suggesting leaving the actuator seeing zero boost.

Exhaust pressure alone is not going to open the wastegate at the cracking pressure This is exactly how EBCs provide gain.

.

.

they show the actuator zero pressure to keep them firmly shut past their cracking pressure until you're closer to your target boost.

If it didn't work, there'd be no point doing it.

shinny wrote:Let's look at it a bit scientifically- on the standard actuator let's say the size of the diaphragm is about 3 times the area of the wastegate

(a bit of a guestimate based on the size of the actuator and the wastegate ports).

If you test the wastegate off the car and it starts moving at 0.5bar, that means the preload of the spring inside is overcome by the force exerted on the diaphragm at 0.5bar.

Now, to get the same force just by applying pressure to the wastegate flap, which is only 1/3rd the area, you would need triple the pressure being applied, ie 1.5bar.

However that's not 1.5bar absolute pressure above atmospheric because there's still some backpressure from the exhaust, so it's only the difference accross the turbine that counts.

AFAIU turbines present backpressure to the enigine proportional to the backpressure presented by the exhaust.

So if a turbine had a 2:1 pressure ratio

(which seems to be a ballpark figure for a CT26 from my googling) and the exhaust presented a pretty high 1bar backpressure, the engine would see 2bar back pressure and the pressure difference acting on the wastegate flap would be 1bar

- still not enough to crack the CT26 wastegate open by my back-of-an-envelope calculations.

With a free flowing exhaust, the absolute pressure difference drops, making it even less likely the exhaust pressure will be able to crack the wastegate.

Rob - East Coast Imports wrote:as for the wastegate, a 38mm wastegate should be adequate for 99% of MR2 set ups, bearing in mind it'll need to be in a place on the manifold thatfeeds from all four runners, so you will loose some of the twin scroll effect.

shinny wrote:From my experience I would agree.I didn't notice the slight loss of twin-scroll, probably because being able to confidently slam the boost in at the desired level beats a perfect twin scroll that's creeping up to your desired boost level.

I've had three different manifold/ turbo combinations with 38mm wastegates.

The only one that has given me creep is the GT28 one and I would put that down to the adaptor taking the dump pipe off at an angle greater than 90º to the gas flow.

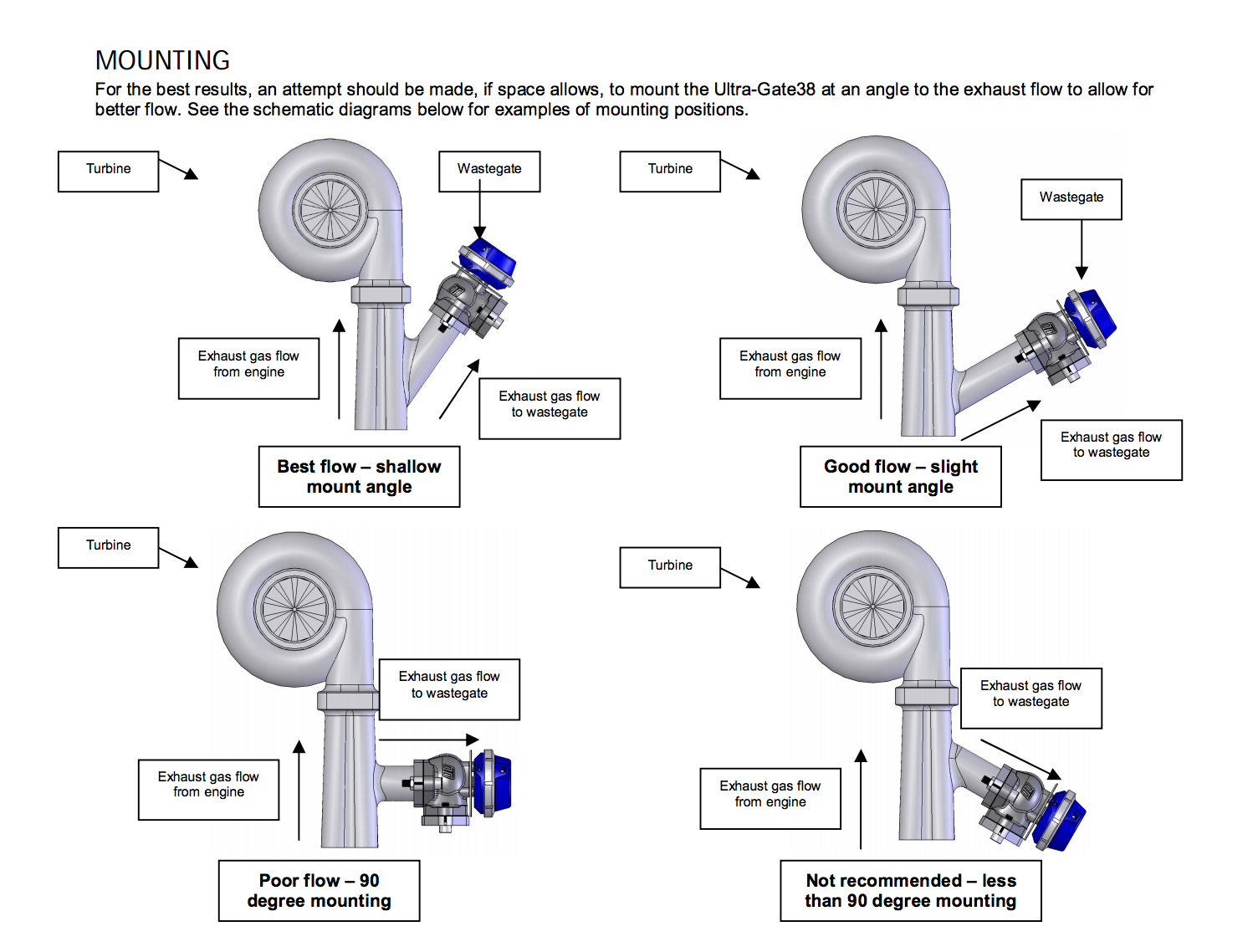

Here's a diagram taken from a turbosmart document to demonstrate how best to add your wastegate:

Image Replaced With URL For Quote

http://shinny.co.uk/toyota/wastegatemounting.png

My GT28 kit has 38mm wastegate on a take-off at 90º to the gas flow which then immediately curves another 45º, so would probably be under the"not recommended" section.

Not a big surprise that it creeps; when making your own wastegate mounting, don't make the same mistake.