There are relatively few transaxles available for inline/mid mount operation.

Then there's old Citroen

QED.

So, look out for an Audi engined

Moderators: IMOC Moderators, IMOC Committee Members

PW@Woodsport wrote:Also i have just bought my exhaust silencer for the project..

.

TVR T350 jobby, it has the correct pipe inlet configuration i am looking for, and the outlets will need modifying.This will be located in my boot which will now be totally dedicated to the exhaust, ECU, Traction control unit, and anything else that's needed.

PW@Woodsport wrote:A question for Alfiembra!

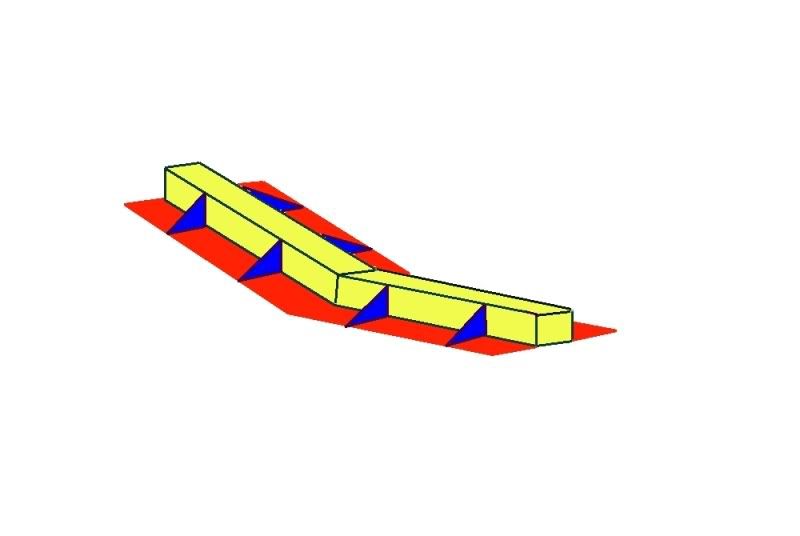

I have put some thought into your suggestion about my engine subframe cradle not being strong enough, and i have revised the design in the drawing below..

.

.

the yellow box section being my current subframe, i was planning on plating the entire underside of the box with 3mm plate

(red area) and adding the blue gussets.

Do you think this is sufficient and/or can you advise on another/better way to do it? Your input is appreciated,cheers!

http://img.photobucket.com/albums/v624/ ... rame-1.jpg