V8 Mk1 6 speed with power steering

Moderators: IMOC Moderators, IMOC Committee Members

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

I noticed my oil filter relocation kit ran fairly close to the exhaust on the right hand bank, so i was just about to start making a shield for it when i found a spare Apexi air filter polished cover and would you believe it bolted right onto the filter housing with the two attachment bolts being in exactly the right place!

I love it when you just pick something up sometimes and it just works.

I love it when you just pick something up sometimes and it just works.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Today i got the V8 started up again but this time on its new Ford VR front pulley trigger assembly because i was getting bad trigger errors somewhere during cranking. Well as soon as i converted to the new setup my trigger errors disappeared, so it must have been a problem with the Deltavag trigger strip on my flywheel.

Well as soon as i converted to the new setup my trigger errors disappeared, so it must have been a problem with the Deltavag trigger strip on my flywheel.

I am also having a problem with clutch disengagement, looks like the Audi clutch i bought is the wrong one for this flywheel, so i am going to buy an Rs4 pressure plate to sort the problem.

I have leak tested my oil filter relocation kit and all is well, so the list of stuff to do now is getting ever smaller.

I am also having a problem with clutch disengagement, looks like the Audi clutch i bought is the wrong one for this flywheel, so i am going to buy an Rs4 pressure plate to sort the problem.

I have leak tested my oil filter relocation kit and all is well, so the list of stuff to do now is getting ever smaller.

-

platmatt8

- Posts: 2114

- Joined: Sun Sep 10, 2006 8:41 pm

- Location: Blackburn (Home of the mighty Rovers)

Re: V8 Mk1 6 speed with power steering

This is possibly the best project i`ve ever read about on this forum, and with the regular updates from yourself it`s awsome to see the story unfold. well done thus far

well done thus far

How many hours would you say has gone into it?

How many hours would you say has gone into it?

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Thanks! Well i have been working on the V8 install now for just over a year, but within that year only maybe one day per fortnight on average of actual work, so that would be roughly 26 working days x8 hours= approx 200 hours which is a lot for just an engine conversion.

I've probably got another 10 hours left in the engine bay and 80-100 hours left in the rest of the car.

I've probably got another 10 hours left in the engine bay and 80-100 hours left in the rest of the car.

-

Neil_turbo

- Posts: 2878

- Joined: Tue Aug 23, 2005 4:27 pm

- Location: Congleton

- Contact:

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Sorry i had a wedding to attend, so no V8 work got done, i am at a standstill anyway until my new Rs4 clutch arrives so fingers crossed that gets here this week.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Another video of this thing running, my iphone just doesn't capture the sheer thunder coming from it, i'm VERY close now to being able to drive it.

http://www.youtube.com/watch?v=poHQGv75vBQ

http://www.youtube.com/watch?v=poHQGv75vBQ

Re: V8 Mk1 6 speed with power steering

That sounds dangerous in a good way.

Is this going to be at JAE this year?

Is this going to be at JAE this year?

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

I doubt it, unless i get a lot more time on the car or trailer it there 75% finished.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

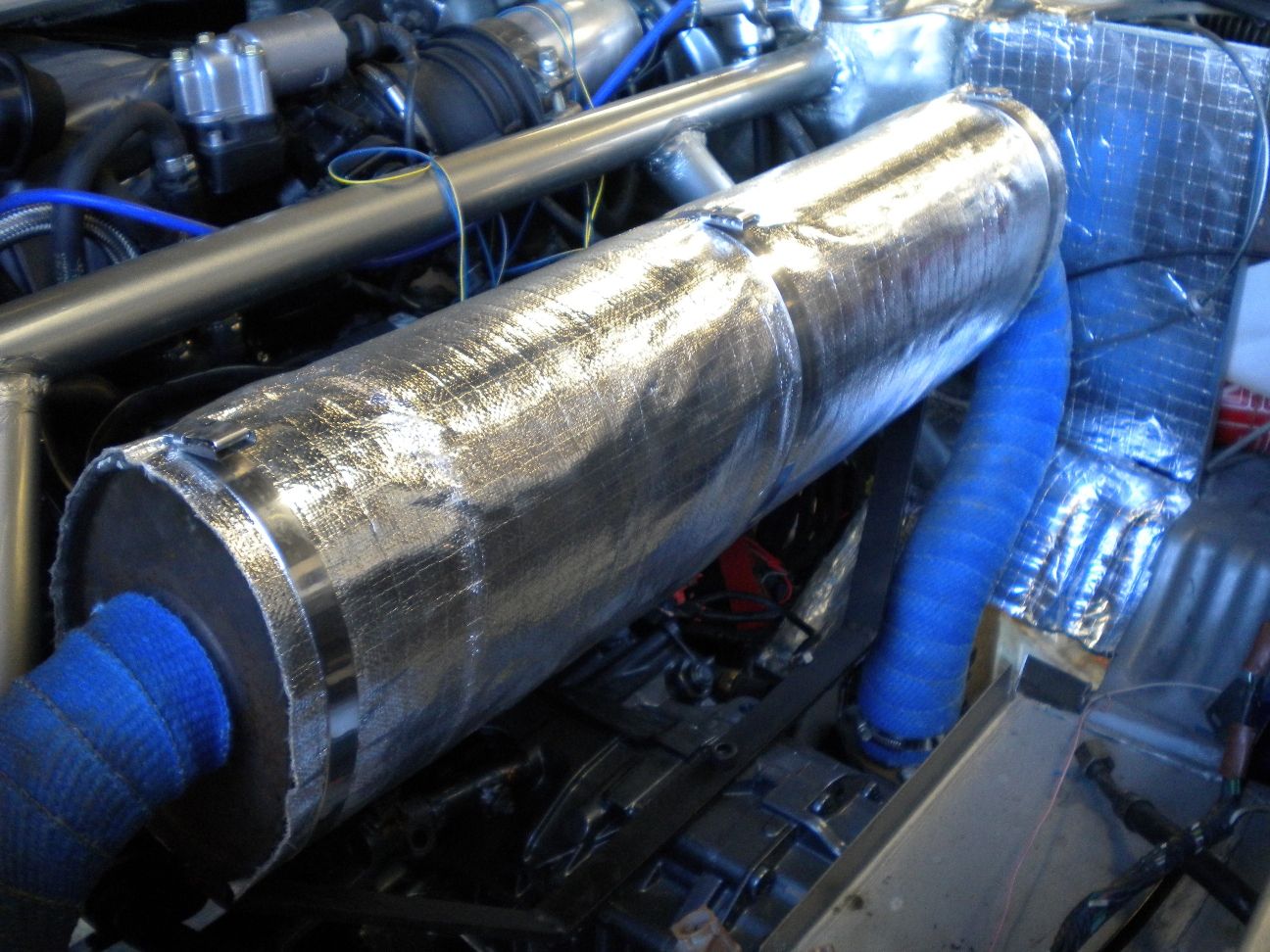

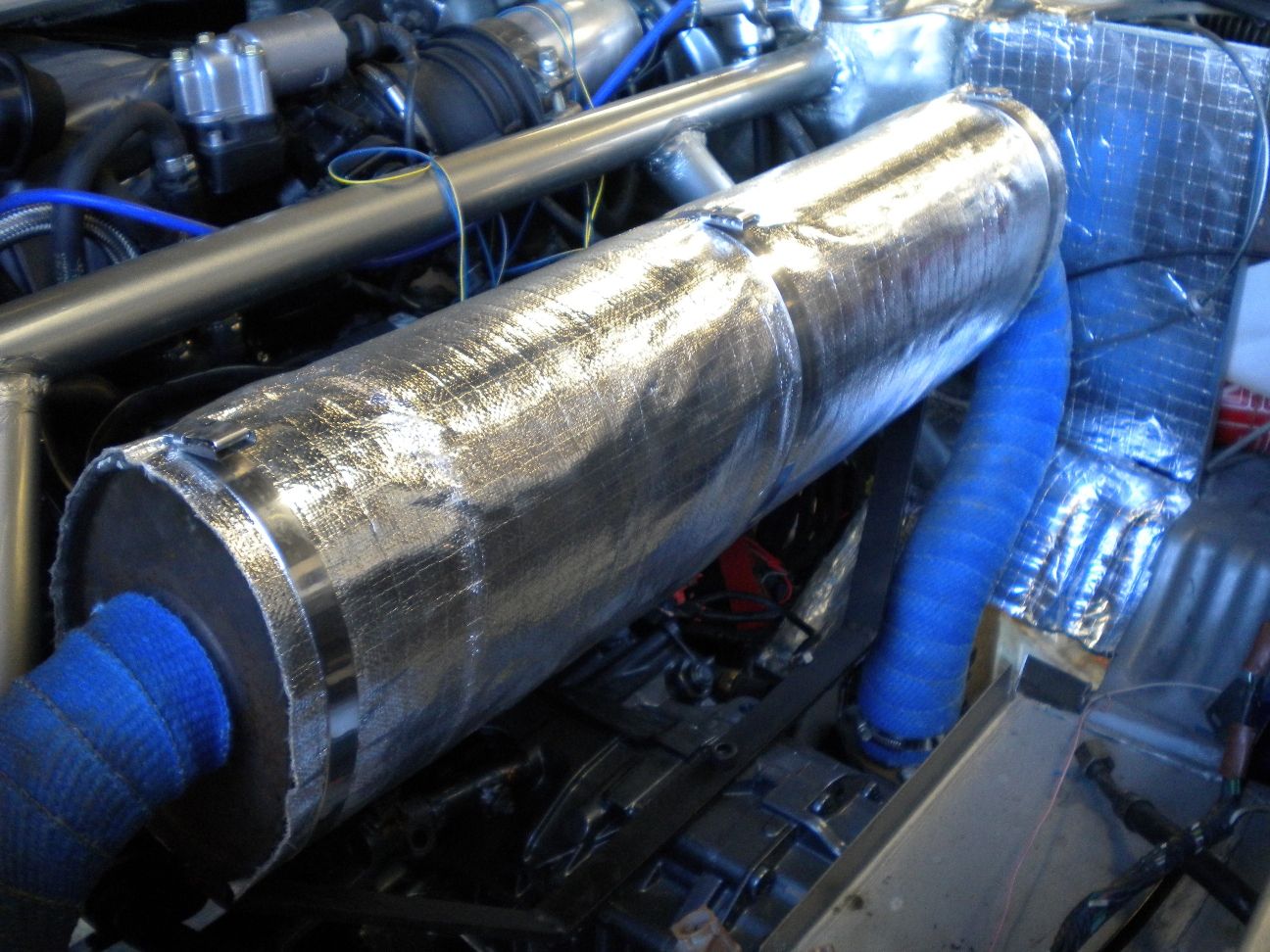

Final finishing off in the engine bay now, i have wrapped my silencer in aluminiumized glass mat in an effort to help keep heat under control. .

. .

. .

.

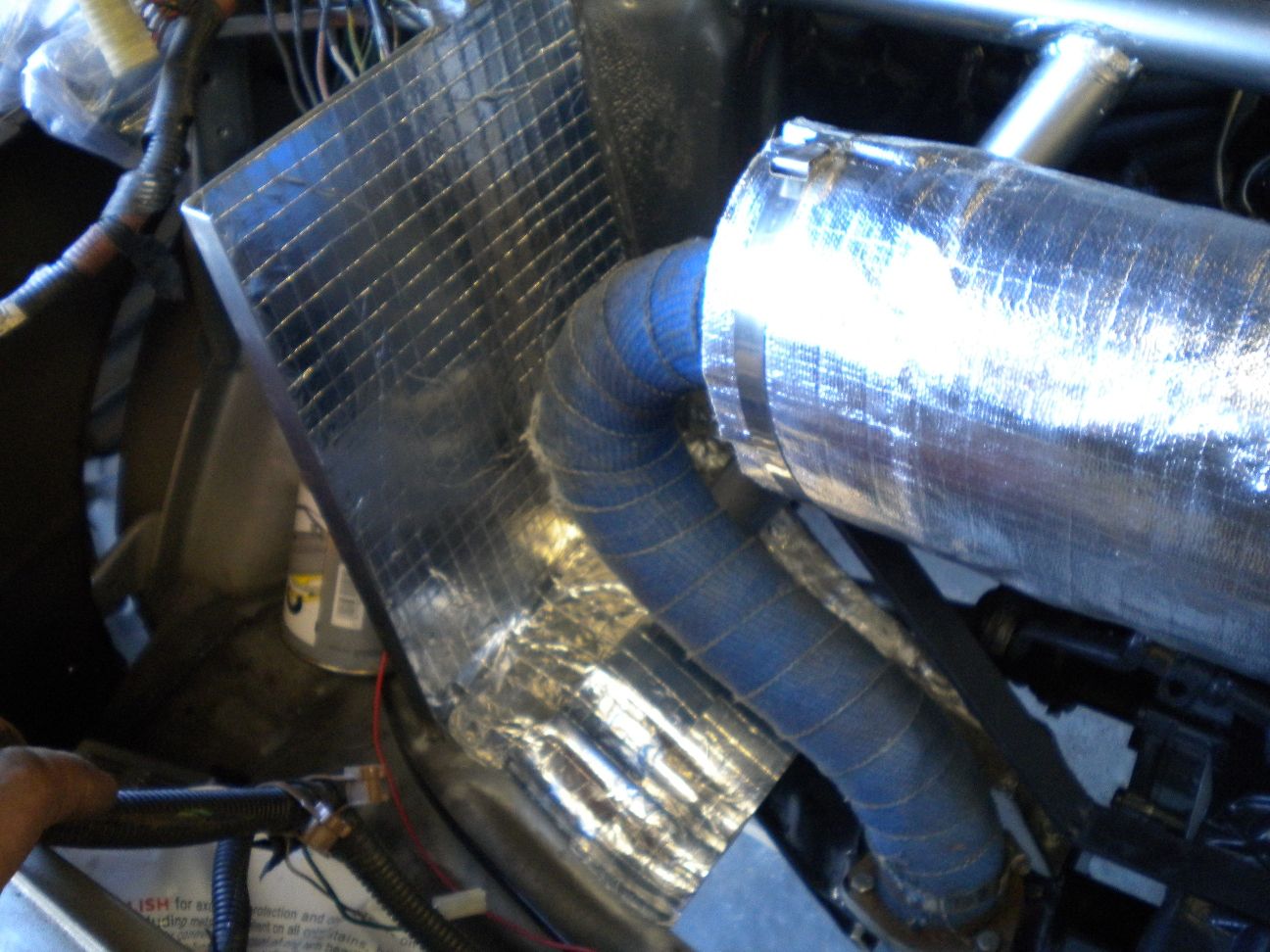

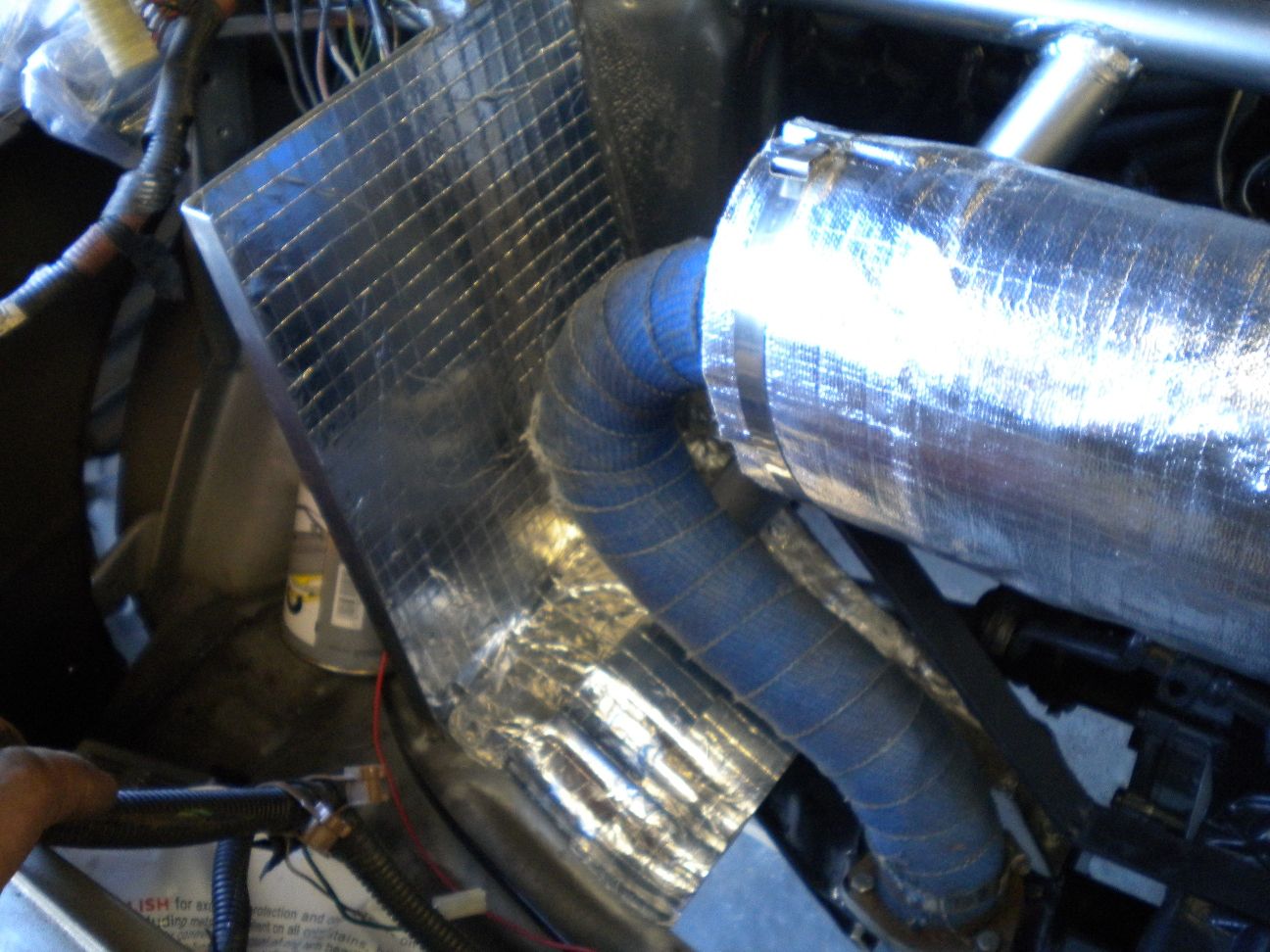

I've also used sticky backed reflective foil on the side walls, this will also go on the rear aluminium wall when that gets fitted. .

. .

.

How effective will all of this heatproofing be? I honestly don't know, but it's got to be better than nothing.

I've also used sticky backed reflective foil on the side walls, this will also go on the rear aluminium wall when that gets fitted.

How effective will all of this heatproofing be? I honestly don't know, but it's got to be better than nothing.

How effective?

Effective enough. We use exactly the same stuff on our rally car, when at full running temp you can still hold your hand on the wrapped silencer.

We use exactly the same stuff on our rally car, when at full running temp you can still hold your hand on the wrapped silencer. From memory I used double thickness all over.

From memory I used double thickness all over.

It makes burning your face off when working under the car after stages a lot less likely. I dont think you will have any problems.

I dont think you will have any problems.

Looking forward to a good drive-by video, it will sound awsome, and stainless exhausts always seem to sound a bit better when hot, not sure if there is any science behind this or it is just my over active imagination.

It makes burning your face off when working under the car after stages a lot less likely.

Looking forward to a good drive-by video, it will sound awsome, and stainless exhausts always seem to sound a bit better when hot, not sure if there is any science behind this or it is just my over active imagination.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

That's good to hear, i am guessing this part of the build.

Not sure about the silencer sounding better when hot? I can't think why it would. .

. .

. i'll have to listen for that now!

i'll have to listen for that now!

Not sure about the silencer sounding better when hot? I can't think why it would.

Re: V8 Mk1 6 speed with power steering

Can't say I noticed any difference in tone but what our rally car sometimes does do when the exhaust is hot is belch 3 foot long flames on the overrun.

On it's first event several folk said it spat bigger flames than the 6R4 that followed it.

On it's first event several folk said it spat bigger flames than the 6R4 that followed it.

It's on 45 DCOEs and may run a wee bit rich.

Our system is wrapped from the header to the tail pipe so with your system fully wrapped it should warm up nicely and that V8 should hopefully do a nice pyrotechnic display.

Our system is wrapped from the header to the tail pipe so with your system fully wrapped it should warm up nicely and that V8 should hopefully do a nice pyrotechnic display.

It's on 45 DCOEs and may run a wee bit rich.

Re: V8 Mk1 6 speed with power steering

PW@Woodsport wrote:Final finishing off in the engine bay now, i have wrapped my silencer in aluminiumized glass mat in an effort to help keep heat under control..

.

.

Do you mean you're not gold-plating the engine bay interior like the McLaren F1

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Believe it or not Mart i did actually look into it, but the costs were just silly.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Today was a good day, no more wiring my engine up to a battery on the floor, the engine is now fully integrated into the car and it now starts up off the key. I still have lots of wiring to do but all of my major signals are fed to the dashboard now.

I still have lots of wiring to do but all of my major signals are fed to the dashboard now. Alternator is hooked up and charging well and all of the cars circuits are alive now.

Alternator is hooked up and charging well and all of the cars circuits are alive now.

My Vems is now safely located out of the engine bay away from the 8 cylinder inferno just behind the drivers seat. .

. .

. .

.

I have left my serial port connector in the bay for mapping, I have an extension lead for it to reach the cockpit if need be. I might make a little bracket for the port if i run out of jobs to do.

I might make a little bracket for the port if i run out of jobs to do.

Lastly i heat shielded all of my engine harness where it runs near the exhaust, i really am giving this as much attention as possible in the heat dept.

My Vems is now safely located out of the engine bay away from the 8 cylinder inferno just behind the drivers seat.

I have left my serial port connector in the bay for mapping, I have an extension lead for it to reach the cockpit if need be.

Lastly i heat shielded all of my engine harness where it runs near the exhaust, i really am giving this as much attention as possible in the heat dept.

-

PW@Woodsport

- Posts: 7642

- Joined: Tue Dec 14, 2004 6:40 pm

- Location: durham

- Contact:

Re: V8 Mk1 6 speed with power steering

Now that the engine dept is almost finished i've turned attention to getting brakes on this thing. I've been hoarding these parts for years so they are a little rusty but i will work some magic on them once i've got them working.

I've been hoarding these parts for years so they are a little rusty but i will work some magic on them once i've got them working.

First i fitted my new master cylinder i got from Gouky, it's a 1" Toyota Van one, although many other Toyota's share the same bore and fitment. The stock Mk1 MC is 7/8ths so this 1" unit will move more fluid to my four pot calipers and reducing pedal travel.

The stock Mk1 MC is 7/8ths so this 1" unit will move more fluid to my four pot calipers and reducing pedal travel. I had to reverse the reservoir as this is a RHD car

I had to reverse the reservoir as this is a RHD car  (MC is from a USDM LHD car) to stop it fouling the brake pipes.

(MC is from a USDM LHD car) to stop it fouling the brake pipes.

The reason for needing more fluid movement is these Porsche 996 calipers, i made my own adapters to bolt them to the hub and i have used a BMW 325mm disc redrilled to 4x100 PCD and a hubcentric spigot ring inserted courtesy of AH-CNC, i need to clean them up a little and paint the calipers but otherwise done.

This should be ample up front to stop the Mk1 V8.

First i fitted my new master cylinder i got from Gouky, it's a 1" Toyota Van one, although many other Toyota's share the same bore and fitment.

The reason for needing more fluid movement is these Porsche 996 calipers, i made my own adapters to bolt them to the hub and i have used a BMW 325mm disc redrilled to 4x100 PCD and a hubcentric spigot ring inserted courtesy of AH-CNC, i need to clean them up a little and paint the calipers but otherwise done.

This should be ample up front to stop the Mk1 V8.

-

castrolfan

- Posts: 64

- Joined: Sat May 08, 2010 10:00 am

Re: V8 Mk1 6 speed with power steering

lol this build is crazy. .

. .

.

i love it!

i love it!

Re: V8 Mk1 6 speed with power steering

Nice going Paul

What brake servo are you using - the original, or the bigger one off an SC

- the original, or the bigger one off an SC  ?

?

What brake servo are you using