JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Moderators: IMOC Moderators, IMOC Committee Members

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

craig wrote:Great job mate, car looks great!

Cheers Bud, now focusing on performance and braking

in the next month or so.

aftermarket ECU.

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Something I've been wanting to do for a while

was to create a "Mod List" so here we are, all of what I can

"Mod List" so here we are, all of what I can

remember off the top of my head, excluding service items etc.

This will be improving and changing for the better soon with Brakes and

engine

E N G I N E:

.

. Phoenix Power side mounted intercooler

Phoenix Power side mounted intercooler

.

. Berk technologies De-Cat pipe

Berk technologies De-Cat pipe

.

. Blitz Nur Spec R full exhaust system

Blitz Nur Spec R full exhaust system

.

. Greddy Type R Adjustable BOV

Greddy Type R Adjustable BOV  / dump valve

/ dump valve

.

. 8MM Magnecor Ignition Lead Kit

8MM Magnecor Ignition Lead Kit

.

. TRD Sports Iridium Sparkplugs

TRD Sports Iridium Sparkplugs  - Grade 7

- Grade 7

.

. Apex Power Intake

Apex Power Intake

.

. TOM's radiator cap

TOM's radiator cap

.

. TRD oil cap

TRD oil cap

.

. BRD gearbox linkage bushes

BRD gearbox linkage bushes

.

. Bosch

Bosch  "supreme power" battery

"supreme power" battery

.

. SAMCO boost pipe hoses

SAMCO boost pipe hoses

.

. Ceramic coated intercooler pipes

Ceramic coated intercooler pipes

C H A S S I S:

.

. Meister R zeta R CRD+ coilovers

Meister R zeta R CRD+ coilovers  ( 3 way adjustable

( 3 way adjustable  )

)

.

. TOMS Front Strut Brace

TOMS Front Strut Brace

.

. TOMS Rear Strut Brace

TOMS Rear Strut Brace

.

. New drop links

New drop links  & bushings all round

& bushings all round

.

. Eibach Camber Bolts

Eibach Camber Bolts  - Front

- Front

.

. Full archwork roll by Arch Enemy

Full archwork roll by Arch Enemy

B R A K E S:

.

. Rev 3 Turbo callipers

Rev 3 Turbo callipers

.

. Chris Wilson

Chris Wilson  "fast road pads"

"fast road pads"

.

. Miller's 300 plus Fluid

Miller's 300 plus Fluid

W H E E L S & T Y R E S:

& T Y R E S:

.

. Front

Front  - Rota Torque's 17x8J et35

- Rota Torque's 17x8J et35

.

. Rear

Rear  - Rota Torque Drifts 17x9J et30

- Rota Torque Drifts 17x9J et30  ( 5mm spacers

( 5mm spacers  )

)

.

. Front

Front  - Yokohama AD08r 215/40/17

- Yokohama AD08r 215/40/17

.

. Rear

Rear  - Yokohama AD08r 235/40/17

- Yokohama AD08r 235/40/17

E X T E R I O R:

.

. Full re-spray by DPM autobody in OEM

Full re-spray by DPM autobody in OEM  "smg"

"smg"

.

. Border carbon bonnet

Border carbon bonnet

.

. Aerocatch Plus flush lock kit

Aerocatch Plus flush lock kit

.

. Aeroware polyurathane front lip

Aeroware polyurathane front lip

.

. Smoothed front bumper

Smoothed front bumper

.

. Greddy Gracer side skirts

Greddy Gracer side skirts

.

. Smoothed GT spec electronically retractable mirrors

Smoothed GT spec electronically retractable mirrors

.

. Phoenix Power rear spats

Phoenix Power rear spats

.

. TRD wing

TRD wing  , with carbon end caps

, with carbon end caps

.

. Rev 5 clear front light units

Rev 5 clear front light units

.

. Raybrig

Raybrig  ( style

( style  ) Crystal headlight units

) Crystal headlight units

.

. UK spec front indicator delete mouldings

UK spec front indicator delete mouldings

.

. Full 70% dark window tint by Auto Eclipse

Full 70% dark window tint by Auto Eclipse

.

. Osram nightbreaker 7000 headlight bulbs

Osram nightbreaker 7000 headlight bulbs

.

. Osram Nightbreaker H3c fog light bulbs

Osram Nightbreaker H3c fog light bulbs

I N T E R I O R :

:

.

. OMP corsica 330mm deep dish wheel

OMP corsica 330mm deep dish wheel  / yellow stitch

/ yellow stitch

.

. MoMo boss wheel adapter

MoMo boss wheel adapter

.

. Corbeau Pro series XL in leather with yellow top stitch x2

Corbeau Pro series XL in leather with yellow top stitch x2

.

. Corbeau Side mounts x2

Corbeau Side mounts x2

.

. Rouge Motorsport ground rails

Rouge Motorsport ground rails

.

. Corbeau lumbar support

Corbeau lumbar support  ( drivers seat

( drivers seat  )

)

.

. TRD duration gear knob

TRD duration gear knob

.

. Sickspeed suede

Sickspeed suede  / yellow stitch gear surround

/ yellow stitch gear surround

.

. Gloss black dash plastics

Gloss black dash plastics

.

. JDM Toyota rescueman 3 security hammer

JDM Toyota rescueman 3 security hammer

.

. JDM OEM toyota footwell flare

JDM OEM toyota footwell flare

.

. Black rev 1 T-Bar headlining

Black rev 1 T-Bar headlining  + tims and shades

+ tims and shades

.

. UK Rev 5 Leather Door cards

UK Rev 5 Leather Door cards

.

. Modified AC unit with Blue bulbs and backlight

Modified AC unit with Blue bulbs and backlight  (

(  Peter G

Peter G  @ SBITS

@ SBITS  )

)

.

. Modified clock

Modified clock  ( blue overlay

( blue overlay  )

)

.

. White 501 LED bulbs in dash

White 501 LED bulbs in dash

A U D I O:

.

. Edge 6.5 Front Speakers

Edge 6.5 Front Speakers

.

. Edge 4 Rear Speakers

Edge 4 Rear Speakers

.

. Sony MEX

Sony MEX  - BT4000U Bluetooth Head unit

- BT4000U Bluetooth Head unit

S E C U R I T Y

.

. Clifford Alarm System 3

Clifford Alarm System 3

S E R V I C E & O I L' S:

& O I L' S:

.

. Redline Mt90 gearbox oil

Redline Mt90 gearbox oil

.

. Fuchs Titan Pro Race R 10w50

Fuchs Titan Pro Race R 10w50

.

. OEM Toyota oil filter

OEM Toyota oil filter

.

. OEM Toyota fuel filter

OEM Toyota fuel filter

was to create a

remember off the top of my head, excluding service items etc.

This will be improving and changing for the better soon with Brakes and

engine

E N G I N E:

C H A S S I S:

B R A K E S:

W H E E L S

E X T E R I O R:

I N T E R I O R

A U D I O:

S E C U R I T Y

S E R V I C E

Last edited by JLW on Fri Aug 19, 2016 10:36 am, edited 3 times in total.

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

-

Magic Beans

- Posts: 4793

- Joined: Thu Nov 24, 2011 1:01 pm

- Contact:

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Magic Beans wrote:That's a lovely looking car

Thanks Pal.

All out on performance now

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

So not the best thing to have to post, but at least it

seems there is a silver lining. Got back from a long days work

Got back from a long days work

the other night, to get a knock at the door from my neighbours.

Turns out another neighbour that I can't stand and also a raging alcoholic

miserable B**CH reversed into the drivers wing and door along with the drivers front wheel then drove off hoping no one saw her , luckily

, luckily

my other decent neighbours did !!

!!

Not a single apology and stinking of booze she gave me her details for insurance,

I got right onto the case and told her insurer that it will go no where else other then DPM !!

!!

Now for the silver lining , I was ridiculously belligerent and managed to get them to accept DPM's estimate without hassle

, I was ridiculously belligerent and managed to get them to accept DPM's estimate without hassle

within 1 day of the damage being done.

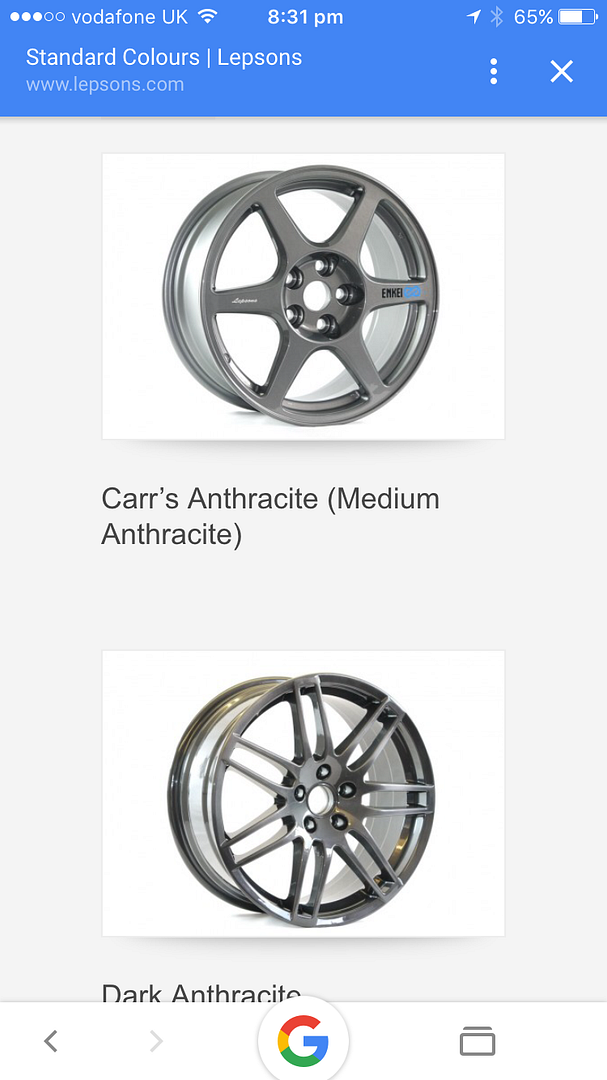

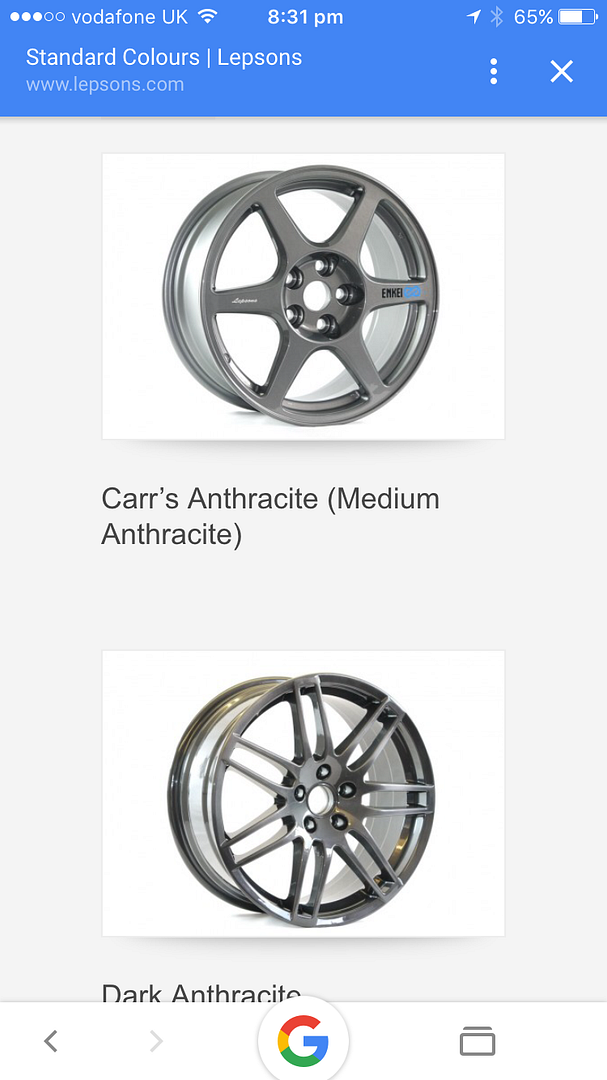

Yes I have just spent literally 2 days on the wheels myself sorting out 2

small curb marks / polishing and sealing.

/ polishing and sealing. However I always wanted them a lighter shade of Gunmetal

However I always wanted them a lighter shade of Gunmetal  / Anthracite.

/ Anthracite.

So here is my opportunity to get them Re-Furbed .

. .

. .

. .

. .

. .Glass half full kinda guy

.Glass half full kinda guy

Thing is the car is due to be showed on DPM's stand at Players on the 18th

which gives us a rush to get the work fixed. But Daves onto it and it will be back to Mint shortly.

But Daves onto it and it will be back to Mint shortly.

Thinking of going for their "Dark Anthracite" colour.

"Dark Anthracite" colour.

seems there is a silver lining.

the other night, to get a knock at the door from my neighbours.

Turns out another neighbour that I can't stand and also a raging alcoholic

miserable B**CH reversed into the drivers wing and door along with the drivers front wheel then drove off hoping no one saw her

my other decent neighbours did

Not a single apology and stinking of booze she gave me her details for insurance,

I got right onto the case and told her insurer that it will go no where else other then DPM

Now for the silver lining

within 1 day of the damage being done.

Yes I have just spent literally 2 days on the wheels myself sorting out 2

small curb marks

So here is my opportunity to get them Re-Furbed

Thing is the car is due to be showed on DPM's stand at Players on the 18th

which gives us a rush to get the work fixed.

Thinking of going for their

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

If I were you mate, I'd watch for her to go out one evening and call 999 with her reg plate. Chances are they will pick her up drunk.

Chances are they will pick her up drunk.

I wouldn't be able to hold my tongue if that was me.

I wouldn't be able to hold my tongue if that was me.

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

So dropped the car down to DPM and a couple of days later started to receive

photo's back of the work along with the strap line of, "got you a little present"

"got you a little present"

Outside of the Insurance claim Dave kindly blasted over the front lip

that looked as though it had been shot blasted with stones from

fast driving and stone chips

He also did the rear grill in gloss black, as this was something we thought

might look nice. Top man

Top man  !

!

And then the photo's of the insurance work to be carried out came through.

At the same time the wheels had returned from Lepsons

from being powder coated in the "Dark Anthracite" colour they

"Dark Anthracite" colour they

offer. They look amazing and the powder coating is 100x better then

They look amazing and the powder coating is 100x better then

the original paint that Rota supplied them in !

!

The car was all back together, minus the Rota's as I had told Dave to leave

these of as I had plans to fit the below custom order. .

. .

. LOVE or HATE mod

LOVE or HATE mod

photo's back of the work along with the strap line of,

Outside of the Insurance claim Dave kindly blasted over the front lip

that looked as though it had been shot blasted with stones from

fast driving and stone chips

He also did the rear grill in gloss black, as this was something we thought

might look nice.

And then the photo's of the insurance work to be carried out came through.

At the same time the wheels had returned from Lepsons

from being powder coated in the

offer.

the original paint that Rota supplied them in

The car was all back together, minus the Rota's as I had told Dave to leave

these of as I had plans to fit the below custom order.

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

How could AD08R's be hate. .

. they are awesome tyres

they are awesome tyres

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Draven wrote:How could AD08R's be hate..

they are awesome tyres

Haha

Amazing tyre and Ill never change.

Tyre Stickers

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Oh no! Tyre stickers hate.

.

. .

. .it's so American.

.it's so American.

Looking superb, I love this car.

Looking superb, I love this car.

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Haha  , as I said.

, as I said. .

. .

. Love or hate.

Love or hate.

I personally love the look, RWB cars are probably my favourite

modified style of car, so have alway's love the painted "Idlers"

"Idlers"

stencil Sakai-San uses

I had it years ago on a stripped and caged mk3

2.0 zetec swapped Fiesta I built, and thought it looked boss. But that

But that

was Type pen. These are permanent rubber adhesive stickers.

These are permanent rubber adhesive stickers.

I personally love the look, RWB cars are probably my favourite

modified style of car, so have alway's love the painted

stencil Sakai-San uses

I had it years ago on a stripped and caged mk3

2.0 zetec swapped Fiesta I built, and thought it looked boss.

was Type pen.

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

androo007 wrote:Oh no! Tyre stickers hate.

.

.

.it's so American.

Looking superb, I love this car.

Oo i see, no they look good.

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

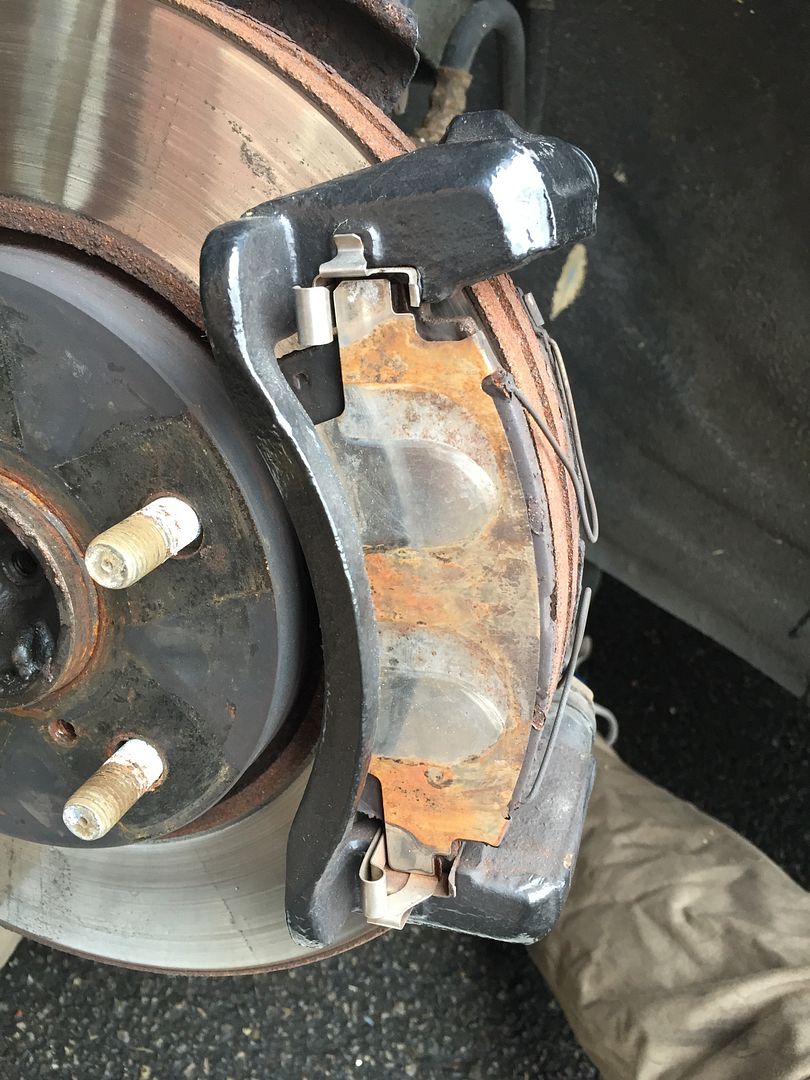

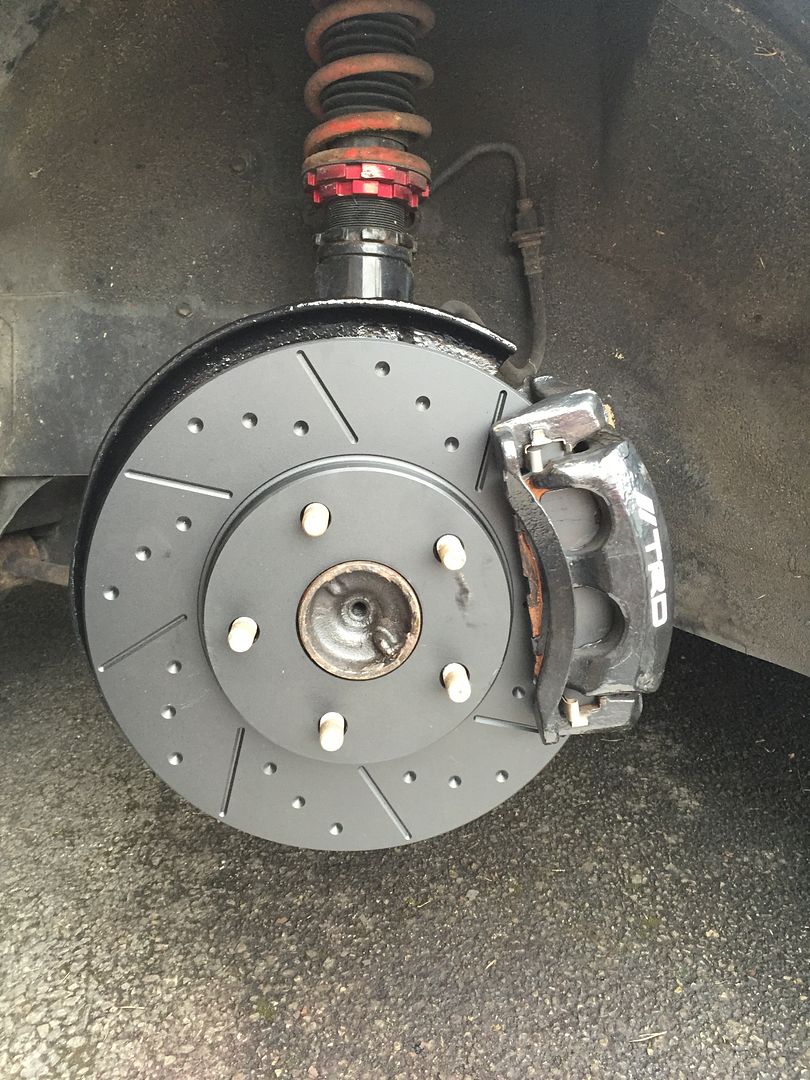

For the last month or so I've been doing research into the best braking system upgrade for my car.

http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Almost unanimously had feedback on here saying that

a "Big Brake Kit" is overkill, and can actually cause more harm then good,

"Big Brake Kit" is overkill, and can actually cause more harm then good,

if the breaking bias is affected adversely. So then it was, whats going to be the

So then it was, whats going to be the

best "disc

"disc  & pad" combonation.

& pad" combonation. After hearing so much Bad news about EBC

After hearing so much Bad news about EBC

products such as their drilled discs and "yellow stuff" pads completely

"yellow stuff" pads completely

disintegrating, I found out about the "Porterfield R4S" fast road and track pad.

"Porterfield R4S" fast road and track pad.

http://www.imoc.co.uk/forums/viewtopic. ... c&start=20

Paul at TCB parts had already advised upon the "MTEC dimpled and Grooved"

"MTEC dimpled and Grooved"

discs and along with a set of "HEL" braided lines and managed to source the

"HEL" braided lines and managed to source the

Porterfield pads. For fluid he has recommended a GULF fluid that performs better then Motul RBF660

For fluid he has recommended a GULF fluid that performs better then Motul RBF660

but for the same price, so thats being ordered shortly as I intended to do the braided lines after discs and pads due to funds.

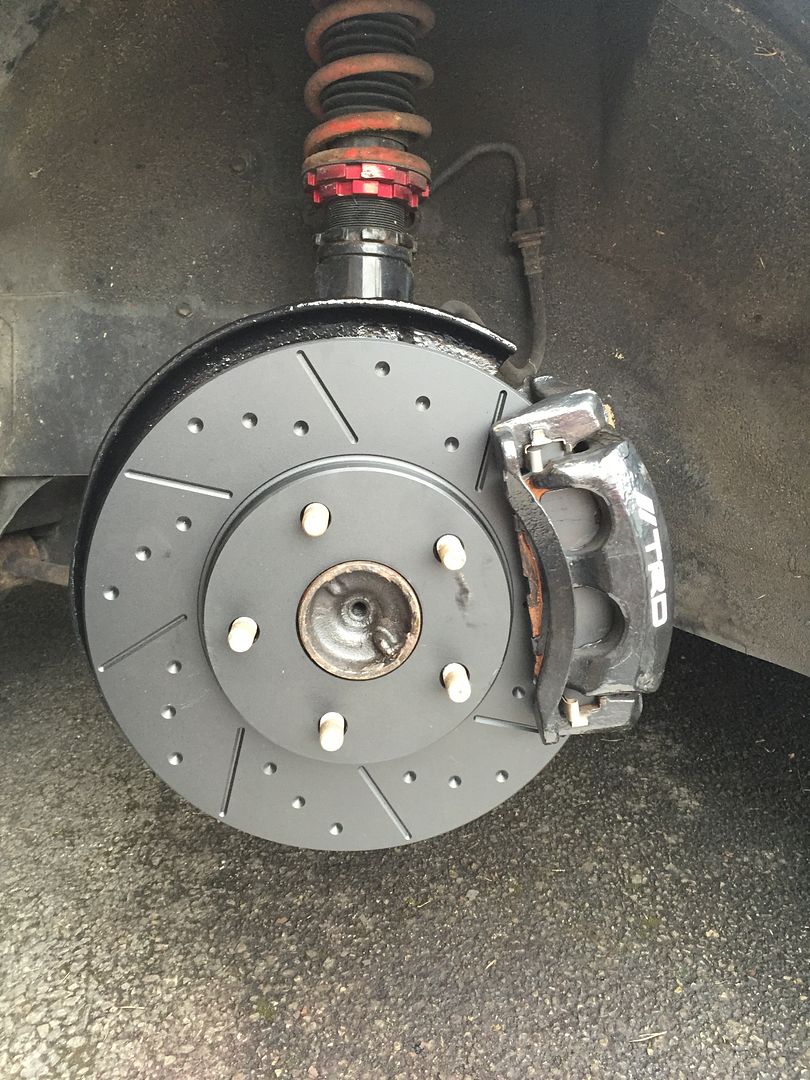

I received through the parts from TCB whilst the car was at DPM, with

the intention of fitting on Friday the 16th.

The reason being is that I left for Paris for work on the 12th due to return on the 15th

late at night, and on the 18th was Players 10th anniversary car show that DPM Autobody had a stand on.

My car was one of 4 to be shown on his stand. It was going to be tight but we thought we could do it.

It was going to be tight but we thought we could do it.

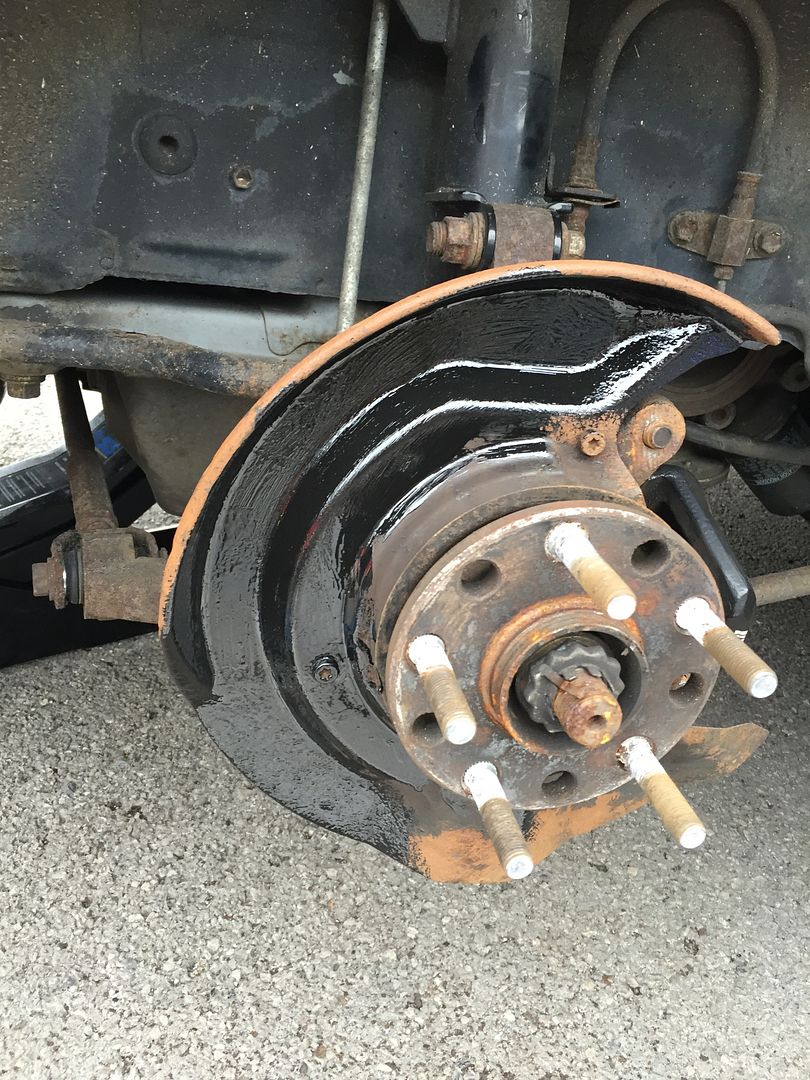

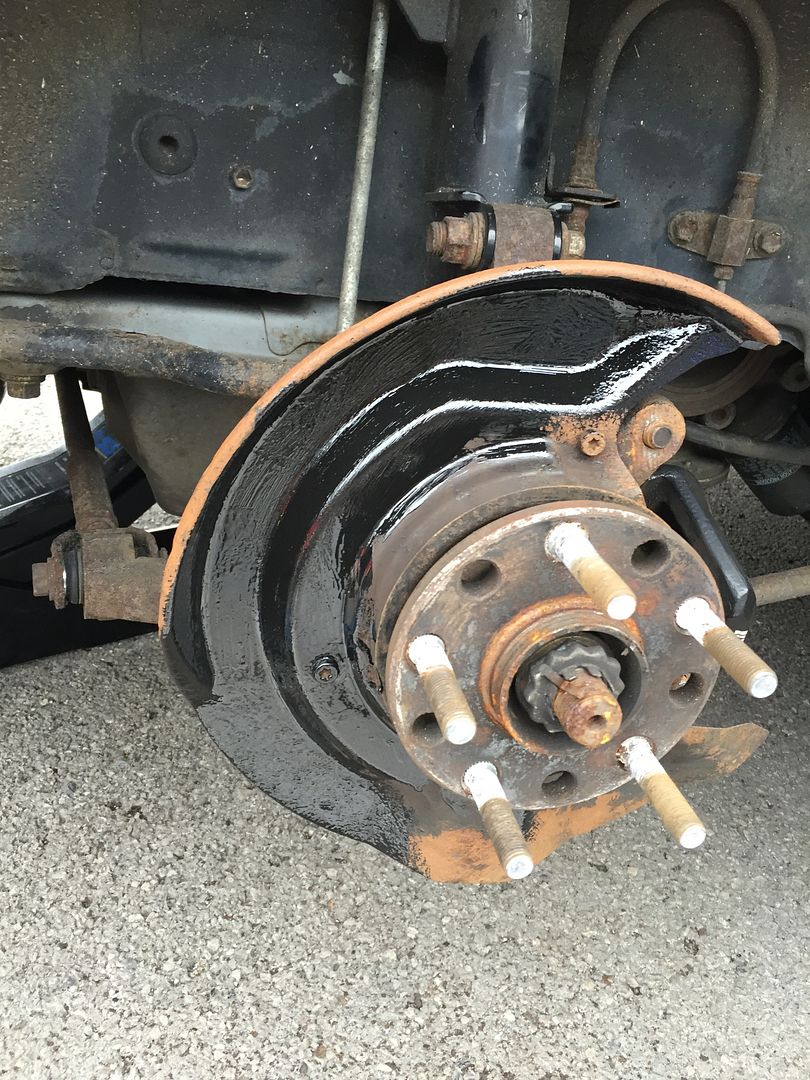

Typically the 16th rained all day, leaving me to swap the discs and pads, and fit the newly re-furbished wheels

on the day before the show. Started with the fronts and had no issue's.

Started with the fronts and had no issue's. At the same time

At the same time

I wanted to give the disc guards a coat of gloss black paint as

they had become brown and rusty over age. I had some of the

I had some of the  "Foliatec"

"Foliatec"

brake calliper paint that I used to do the callipers last year so used that.

Gave them a good wire brushing and cleaned off with brake cleaner

then a lick of paint.

Re-Assembled and with new pads and discs and a liberal coating of copper grease in the required areas.

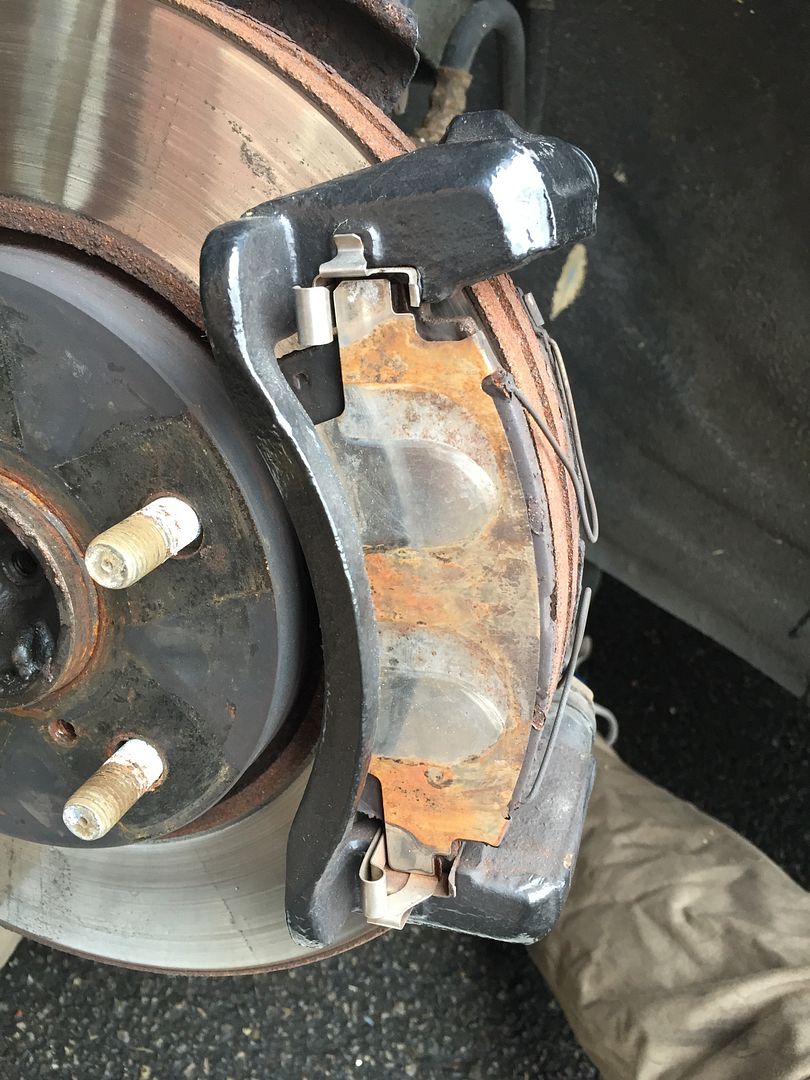

Then I repeated the same process for the rear's, but this is clearly when problems

started to arise.

During the fitting process of the new discs and pads I knew that the pistons had to be pushed back in on the front,

but had done this before with relative ease using just my thumbs !

!  , This time however it needed a G clamp

, This time however it needed a G clamp

to get them to slide back in. This was nothing in comparison to the rear

This was nothing in comparison to the rear

pistons, I didn't actually have a calliper winding tool and had to leave what I

was doing and drive to a neighbours local garage to lend one.

Upon using the tool it became apparent that they were not in perfect order,

as it took all my strength to wind it back in on both sides. It got so bad on the

It got so bad on the

drivers rear that i had to use a lever bar on the tool to get the slots of the piston in the right location for the pads to line up !!

!!

This should have been a warning sign of things to come, but I'm only a basic mechanic on my own vehicles.

Anyway car back together finally at 6pm ( started at 11:30am

( started at 11:30am  )

)

and it was time for a test drive.

A mate jumped in with me and we took it to the next village and back

doing a process that Paul at TCB explained would be the best to bed in the new

brake setup with.

1st heat cycle:

5 x 40-15mph slow downs with conservative pressure

allow to cool for 30 mins

2nd heat cycle:

5x 60-15mph slow downs, increasing pressure on each one. ending with

ending with

large presssure.

Cool down.

We applied the 1st heat cycle treatment, with lots of noises

coming from the brakes that seemed to be the coating of the discs

wearing off possibly. Then got back to the garages.

Then got back to the garages. This is where I possibly didn't

This is where I possibly didn't

help by applying the hand brake !

!  , left the car for 5 minutes then tried to drive it down to the house.

, left the car for 5 minutes then tried to drive it down to the house.

As soon as the wheels made one full rotation there was large bang and a big sensation through the pedal,

leaving a white mark on the passenger side rear disc.

This we now think is because applying the hand brake with the pads still not cooled and being Carbon / Kevlar,

/ Kevlar,

They stuck to the pads surface. The car kept on making a large knocking noise

The car kept on making a large knocking noise

each time the wheels would complete one full rotation that was made

100x worse if you applied the brakes.

No Players show for me

was properly F++king gutted and

was properly F++king gutted and

with all that we had done to get the car ready in time, felt I had screwed it all

up. That night Gazza

That night Gazza  & Paul were really helpful and mentioned it could be the hand brake cables.

& Paul were really helpful and mentioned it could be the hand brake cables.

so at 6:30am Sunday morning there I was removing them.

But it made no difference. Clearly in Hindsight and since speaking to people

Clearly in Hindsight and since speaking to people

it sounds like the rear callipers are binding and the extra spacing needed and much more bite on the new pads

have just shown up an issue that was probably apparent before hand.

Silver lining I guess is that now I know they were not perfect before hand.

So Sunday was now reserved for heavy drinking to waste away the sorrows

of missing something I had been looking forward to for a while.

Anyway I had recently met a couple of guys that started a company called

"Accelerated motor repairs" that did so after leaving Abbey motorsport

"Accelerated motor repairs" that did so after leaving Abbey motorsport

at a local car show. One of which has a Time Attack EVO 8 and the other

One of which has a Time Attack EVO 8 and the other

"20k's worth of MR2 Turbo" so Ive booked them in to re-build all the callipers if and fit the braided lines and put the new fluid in.

"20k's worth of MR2 Turbo" so Ive booked them in to re-build all the callipers if and fit the braided lines and put the new fluid in.

Along with new hand brake cables.

At least ill have the best braking setup I could have once its done.

http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Almost unanimously had feedback on here saying that

a

if the breaking bias is affected adversely.

best

products such as their drilled discs and

disintegrating, I found out about the

http://www.imoc.co.uk/forums/viewtopic. ... c&start=20

Paul at TCB parts had already advised upon the

discs and along with a set of

Porterfield pads.

but for the same price, so thats being ordered shortly as I intended to do the braided lines after discs and pads due to funds.

I received through the parts from TCB whilst the car was at DPM, with

the intention of fitting on Friday the 16th.

The reason being is that I left for Paris for work on the 12th due to return on the 15th

late at night, and on the 18th was Players 10th anniversary car show that DPM Autobody had a stand on.

My car was one of 4 to be shown on his stand.

Typically the 16th rained all day, leaving me to swap the discs and pads, and fit the newly re-furbished wheels

on the day before the show.

I wanted to give the disc guards a coat of gloss black paint as

they had become brown and rusty over age.

brake calliper paint that I used to do the callipers last year so used that.

Gave them a good wire brushing and cleaned off with brake cleaner

then a lick of paint.

Re-Assembled and with new pads and discs and a liberal coating of copper grease in the required areas.

Then I repeated the same process for the rear's, but this is clearly when problems

started to arise.

During the fitting process of the new discs and pads I knew that the pistons had to be pushed back in on the front,

but had done this before with relative ease using just my thumbs

to get them to slide back in.

pistons, I didn't actually have a calliper winding tool and had to leave what I

was doing and drive to a neighbours local garage to lend one.

Upon using the tool it became apparent that they were not in perfect order,

as it took all my strength to wind it back in on both sides.

drivers rear that i had to use a lever bar on the tool to get the slots of the piston in the right location for the pads to line up

This should have been a warning sign of things to come, but I'm only a basic mechanic on my own vehicles.

Anyway car back together finally at 6pm

and it was time for a test drive.

A mate jumped in with me and we took it to the next village and back

doing a process that Paul at TCB explained would be the best to bed in the new

brake setup with.

1st heat cycle:

5 x 40-15mph slow downs with conservative pressure

allow to cool for 30 mins

2nd heat cycle:

5x 60-15mph slow downs, increasing pressure on each one.

large presssure.

Cool down.

We applied the 1st heat cycle treatment, with lots of noises

coming from the brakes that seemed to be the coating of the discs

wearing off possibly.

help by applying the hand brake

As soon as the wheels made one full rotation there was large bang and a big sensation through the pedal,

leaving a white mark on the passenger side rear disc.

This we now think is because applying the hand brake with the pads still not cooled and being Carbon

They stuck to the pads surface.

each time the wheels would complete one full rotation that was made

100x worse if you applied the brakes.

No Players show for me

with all that we had done to get the car ready in time, felt I had screwed it all

up.

so at 6:30am Sunday morning there I was removing them.

But it made no difference.

it sounds like the rear callipers are binding and the extra spacing needed and much more bite on the new pads

have just shown up an issue that was probably apparent before hand.

Silver lining I guess is that now I know they were not perfect before hand.

So Sunday was now reserved for heavy drinking to waste away the sorrows

of missing something I had been looking forward to for a while.

Anyway I had recently met a couple of guys that started a company called

at a local car show.

Along with new hand brake cables.

At least ill have the best braking setup I could have once its done.

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

You'll be surprised at how good they are once the caliper rebuild is done  - the stock brakes with good pads are very capable

- the stock brakes with good pads are very capable

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

yeah I'm sure they will be mate, at the end of the day I cannot imagine in 21 years, they have ever been re-built. So its about time.

So its about time.

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Sad times,

those disks look epic though.

those disks look epic though.

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

JLW wrote:yeah I'm sure they will be mate, at the end of the day I cannot imagine in 21 years, they have ever been re-built.So its about time.

Yeah, one of those things with MR2's.

As long as they are rebuilt properly with all new bits inc.

Will get a link for the grease, two mins.

Re: JLW's ( REV 3 GT spec Turbo, smg Tbar ) YVS Performance Built

Cheers bud, I'm just trying to figure out whats going to be cheaper.

either the company carrying out the work buys the £15 rebuild kits from

£15 rebuild kits from

"Big Red" and re-builds each one.

"Big Red" and re-builds each one.

Or TCB have quoted me a price of £341 for 4 fully re-built and re-conditoned callipers.

£341 for 4 fully re-built and re-conditoned callipers.

Its basically how long will it take to re-build my ones vs new ones ?

?

either the company carrying out the work buys the

Or TCB have quoted me a price of

Its basically how long will it take to re-build my ones vs new ones

BUILD THREAD  : http://www.imoc.co.uk/forums/viewtopic. ... highlight=

: http://www.imoc.co.uk/forums/viewtopic. ... highlight=