Anyway the top Subaru idler i used, Gouky brought it to my attention that i had used a cambelt idler and not a serpentine belt one, i'm like so what? It was then he opened my eyes to the bearings maximum operating speed, something i had not even considered!

Cam belts move at around 0.65ft/revolution due to the small crank cog, but serpentine crank pulleys are 2 or 3 times as big, meaning you can nearly triple the belt speed, so my Subaru idler is used to seeing maximum speeds of around 16,000 rpm

That is just not acceptable, and i suspect it would turn into a skateboard wheel very quickly at those speeds, so huge thanks to Gouky for bringing that to my attention.

Today i redesigned the top idler and used the same one Lotus use in the Evora, it is meant to be seeing 40k rpm speeds.

New top idler.

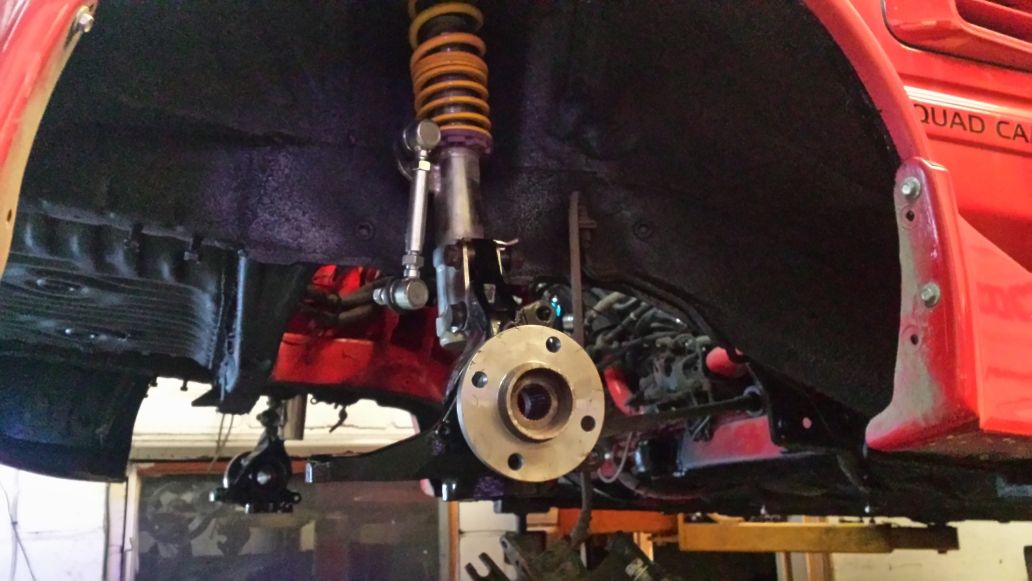

Also the car is getting a full running gear restoration at the same time, all of my suspension arms, hubs, subframes and brake dust shields have been shot blasted and powder coated, i have fitted a new polybush kit and all new balljoints and wheel bearings etc, this year i want it to look as good underneath as it does elsewhere.